Here i am again with Something i looked forward to for a long while: a HK B-25J model.

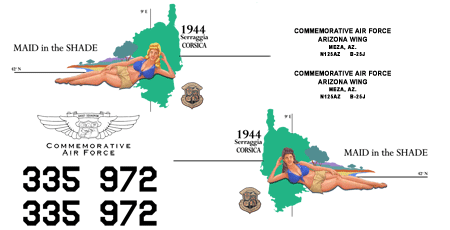

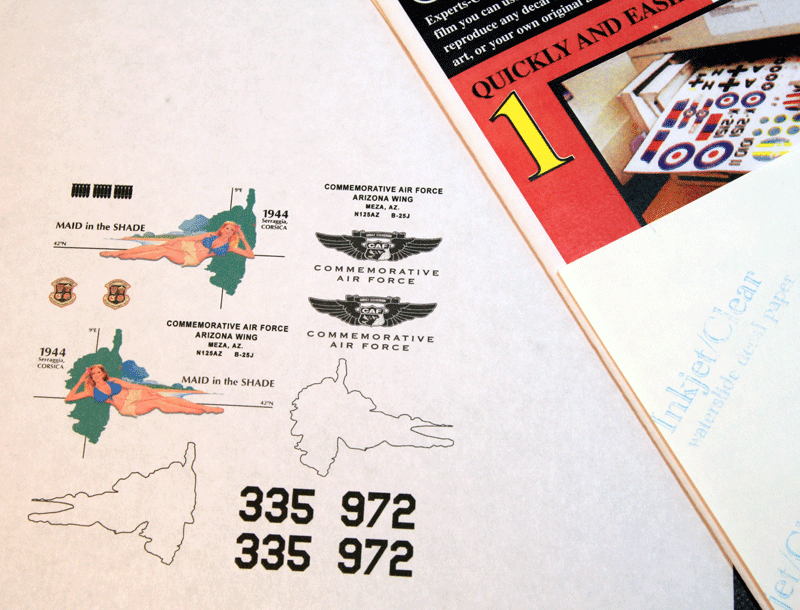

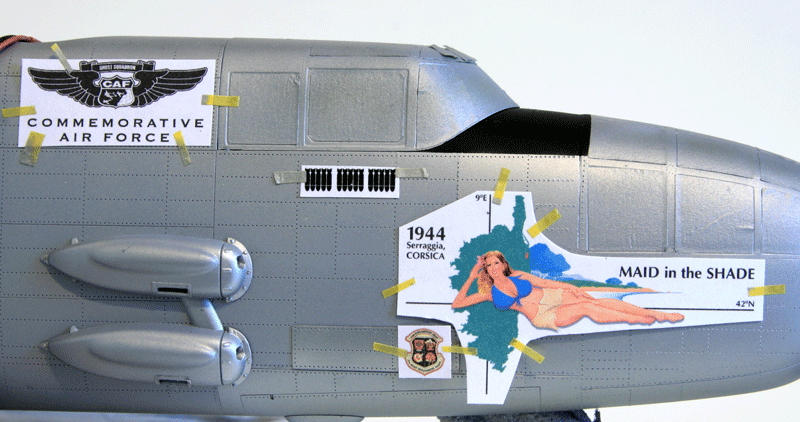

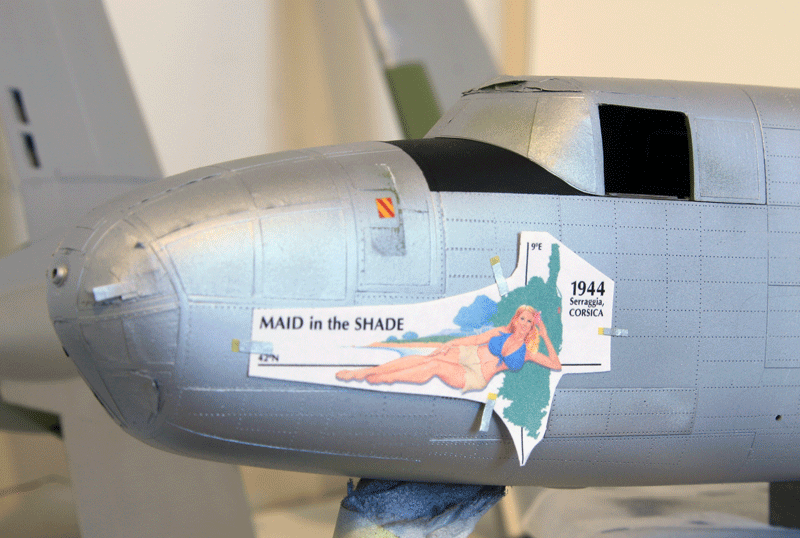

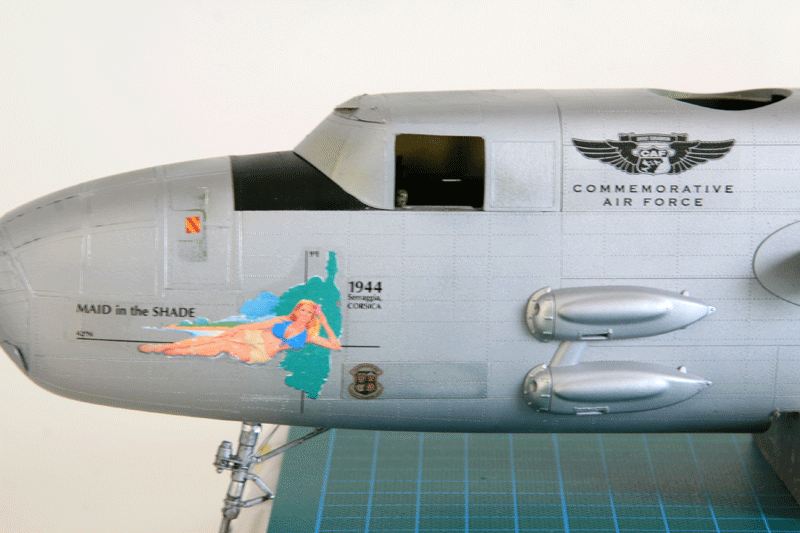

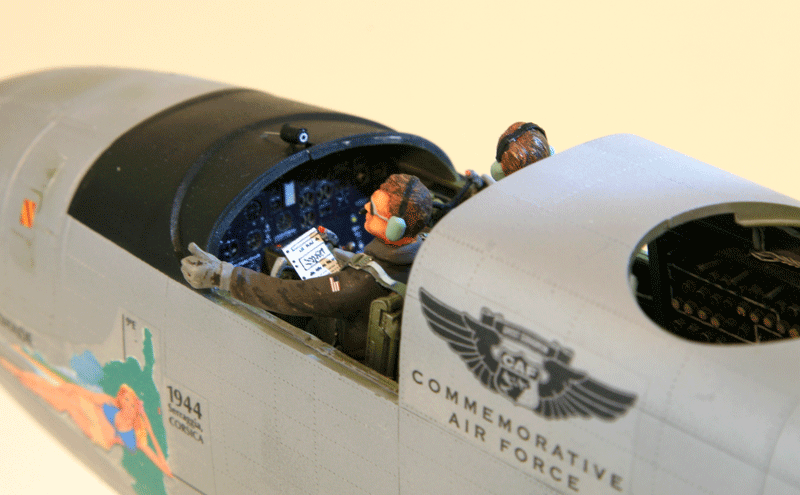

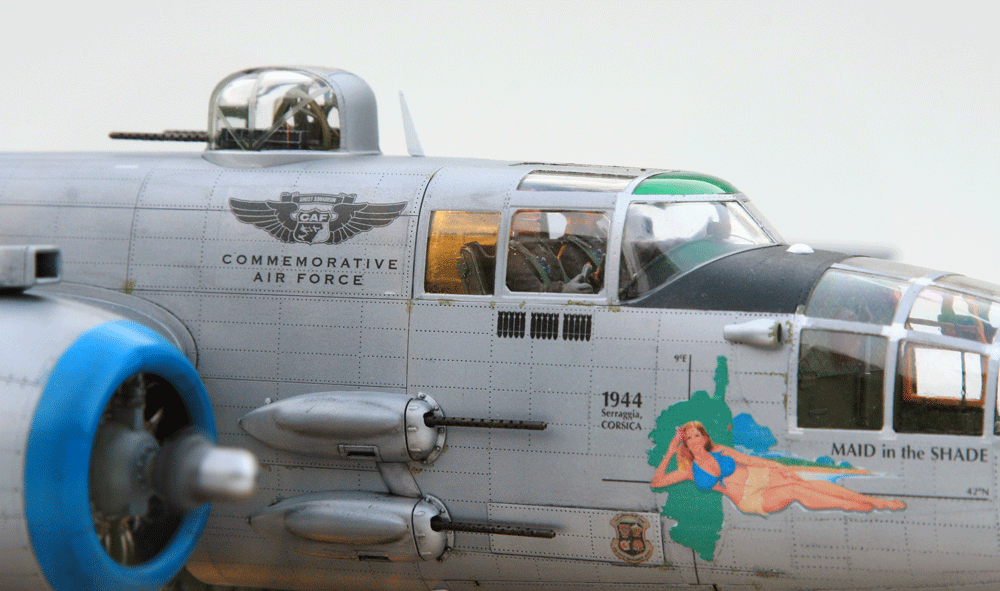

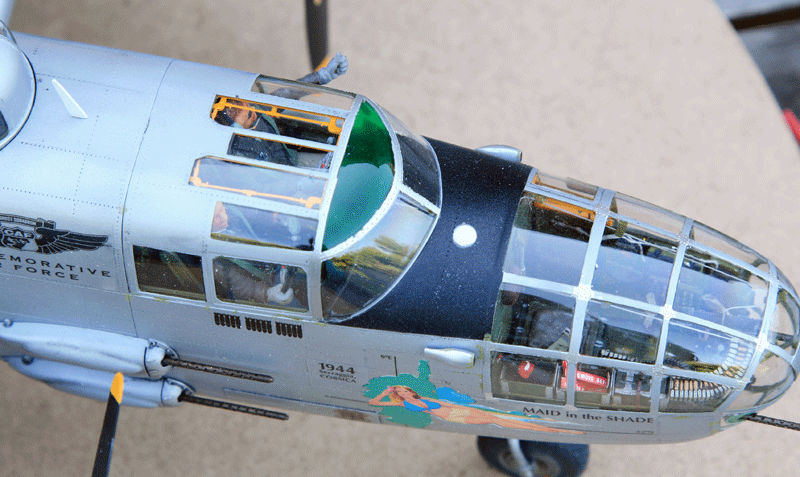

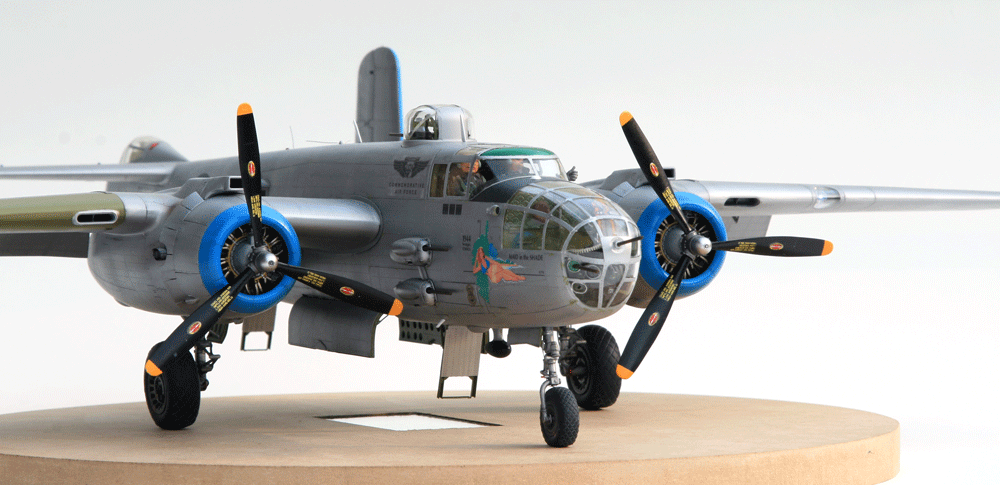

The B-25 will be the Maid in the Shade currently part of the Commemorative air force in Arizona.

The build will create a few challenges:

- Obviously the interior has been adapted to air rides rather than combat. Although the guns are still installed there are lots of seats all over the forward and aft cabin. I'm not sure I'll be able to make the internals as the modern restored aircraft, especially considering that most of all this will be invisible once assembled.

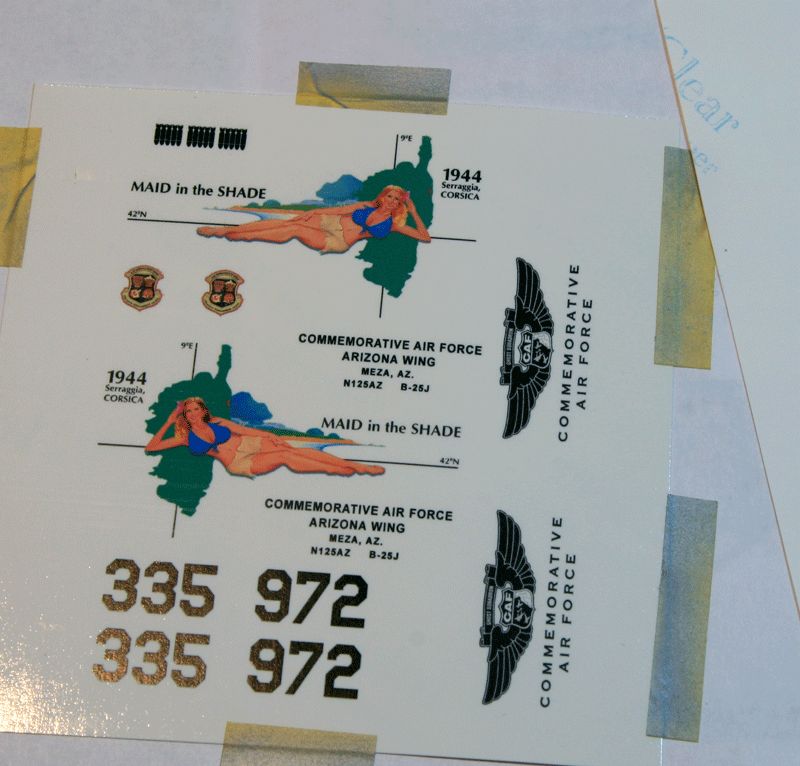

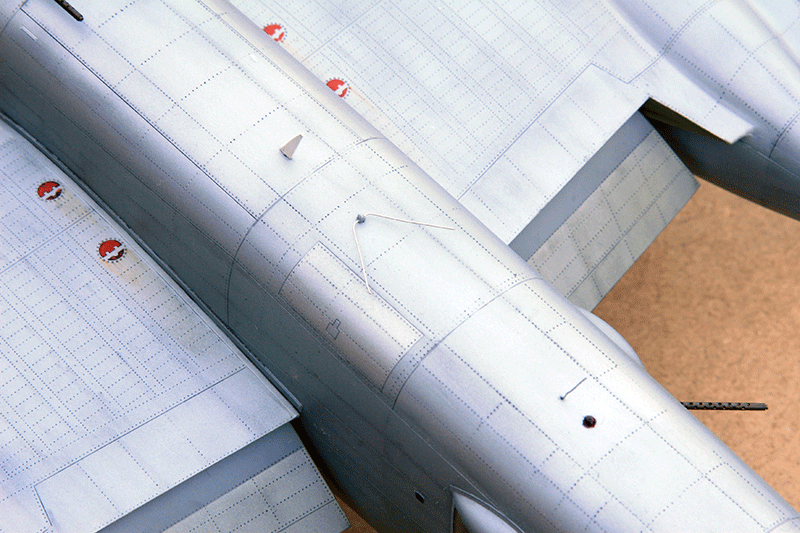

- The natural metal finish will be interesting as well and of course there is no decal for this one - well not that i know of. So i had to design my own. the larger decals (national insignias and tail numbers will be painted with masks as illustrated in the other blogs articles.

The decals are not final yet, just a work in progress when I need a break from the bench.

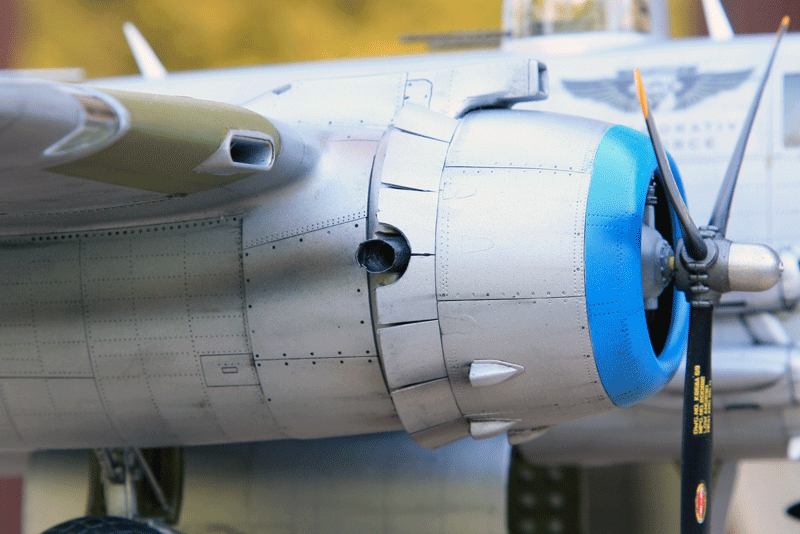

- The biggest issue for me will be the need to convert the engine exhaust from the full Clayton of the model to the modified Clayton that restored B-25 usually have. Some of the top cowling individual exhausts are collected into one larger side exhaust pipe and the carburetor intake on top of the wing is much larger and rectangular in shape.

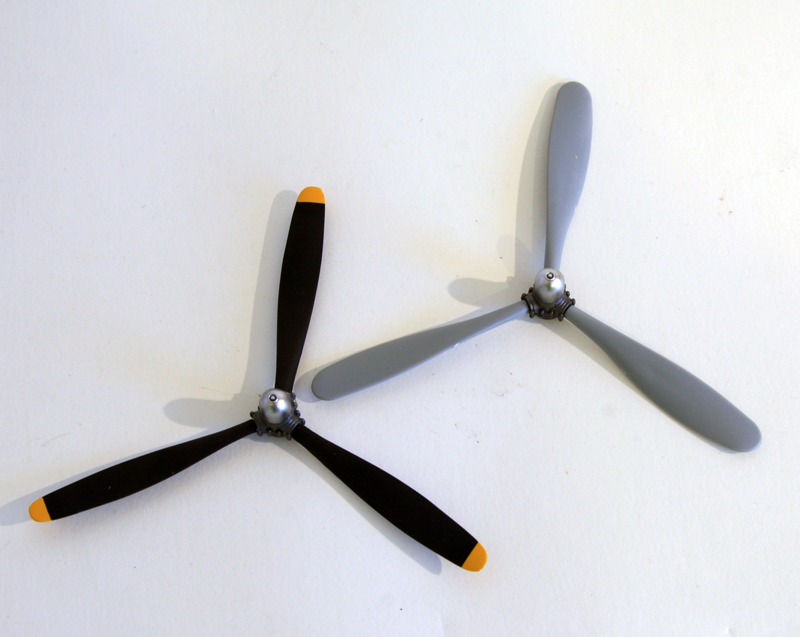

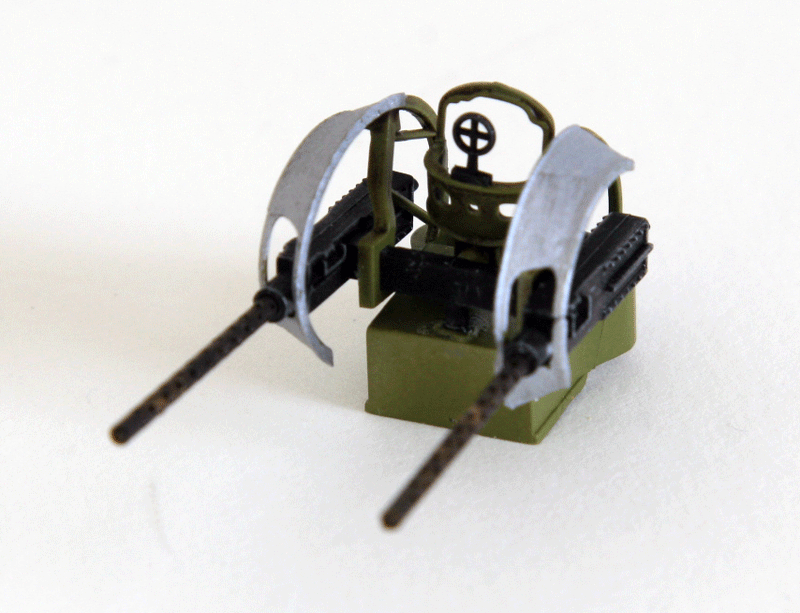

- The model will use a bit of aftermarket products such as the usual Eduard PE sheets, AMS props, Brassin wheels, brass gears and turned barrels for the .50s. Not forgetting the much needed nose weight.

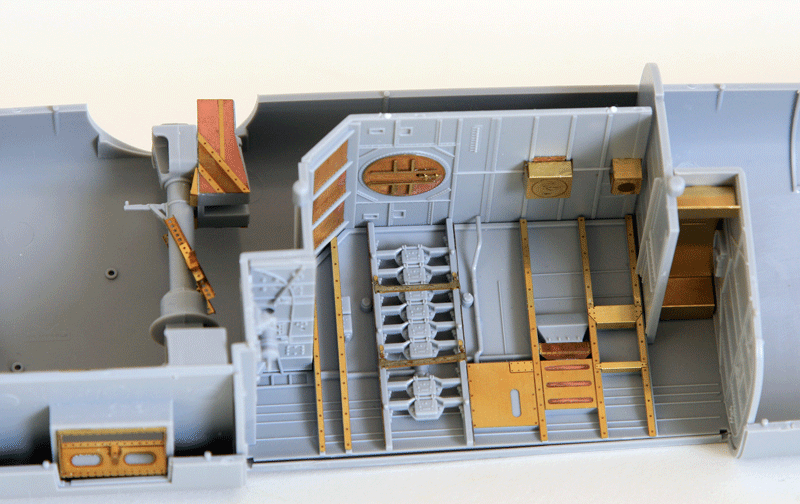

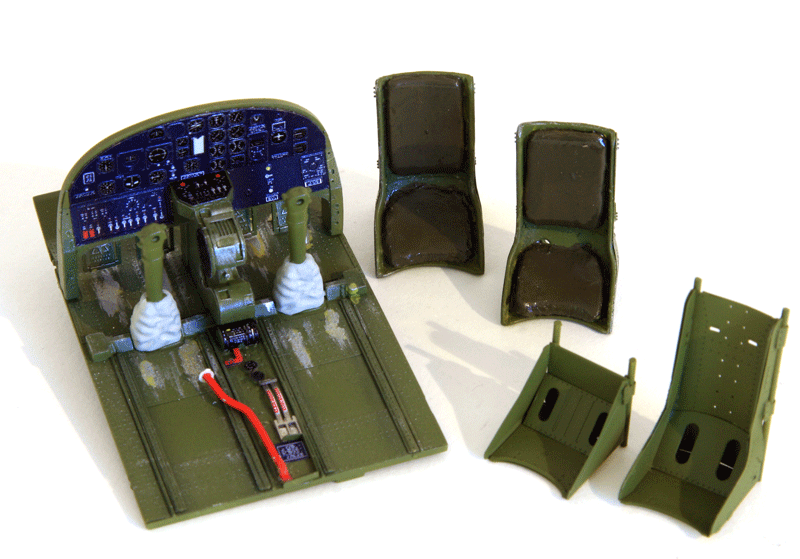

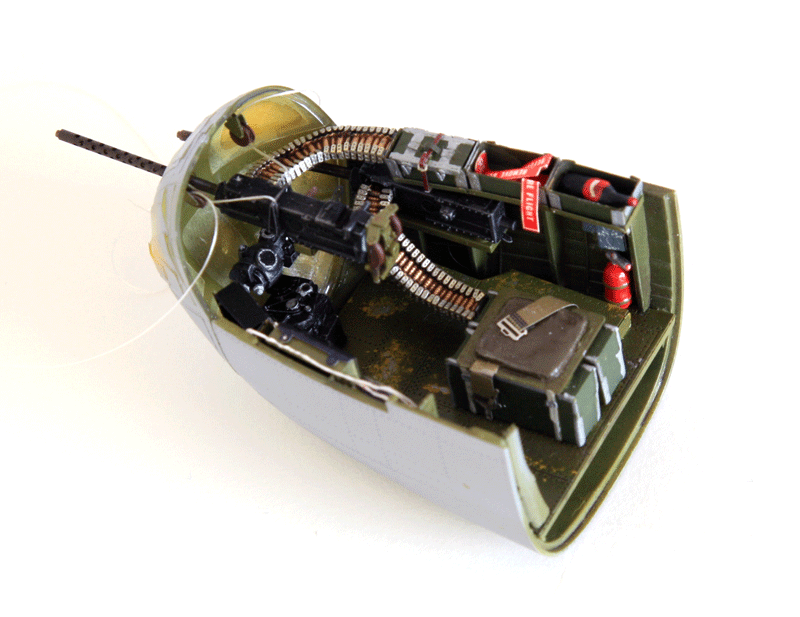

Let's start with the internal work and some PE fun with the Eduard sheets for the B-25J:

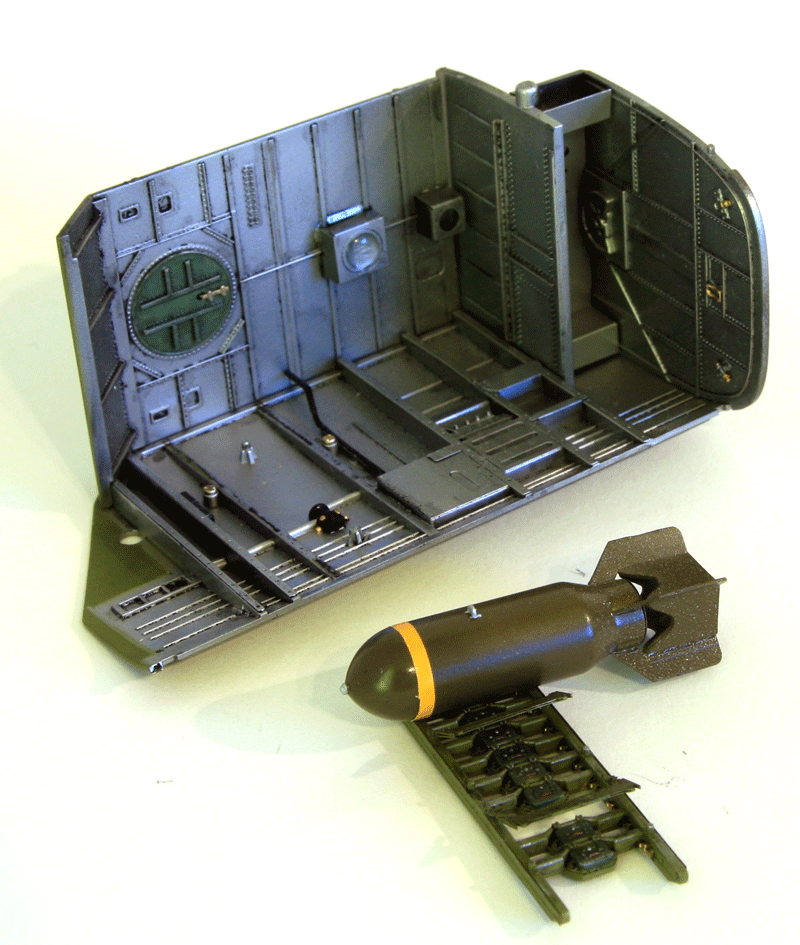

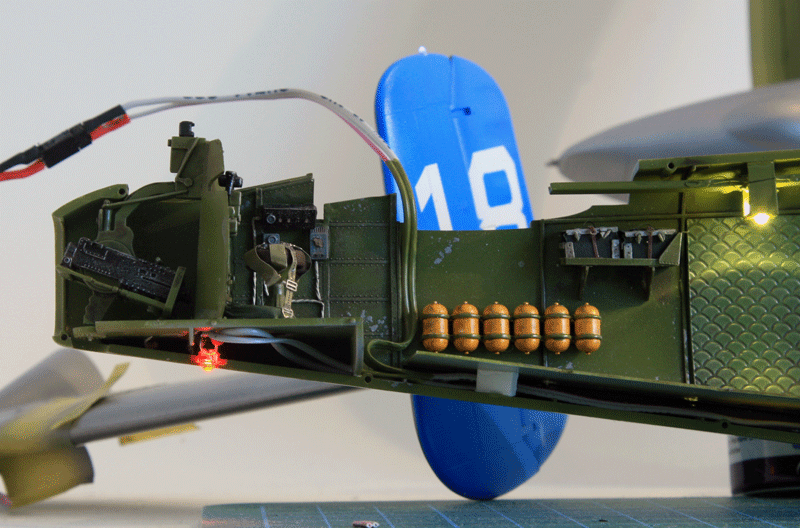

bomb bay

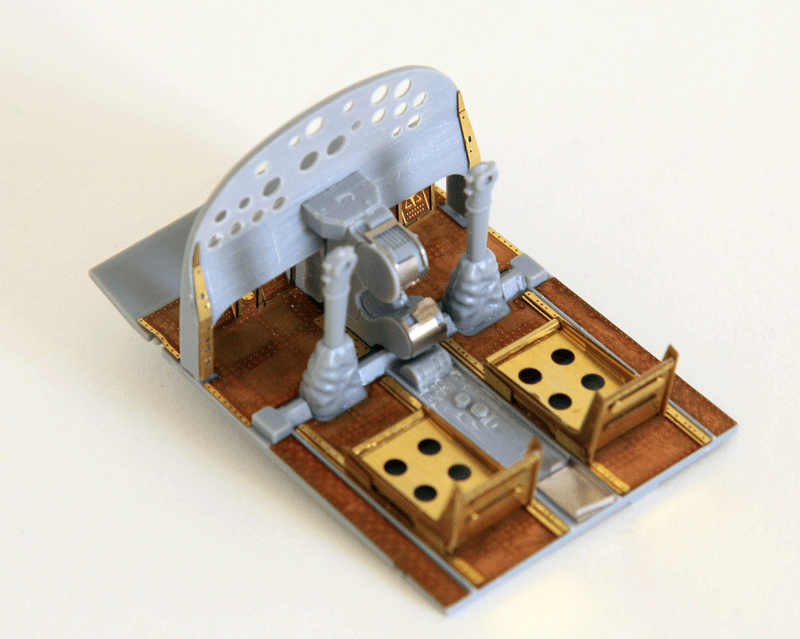

Cockpit

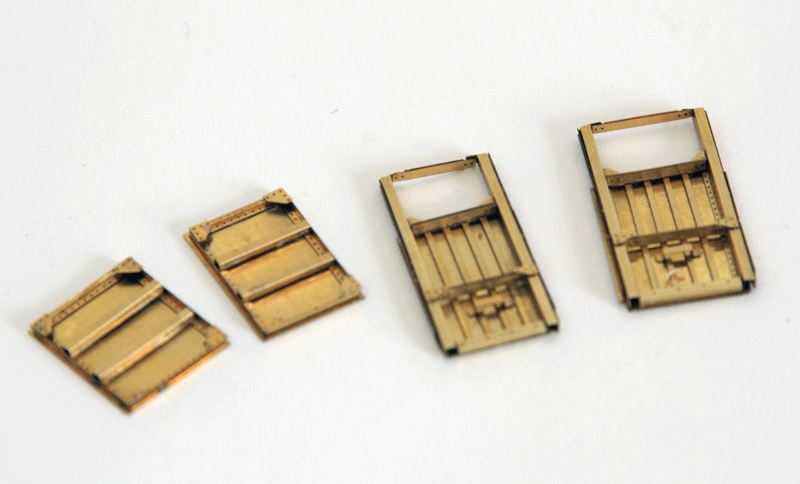

Access doors

There is a narrow and wide door and if you follow the instructions the inner wall details PE fret won't fit the kit's parts. As they are too wide or too narrow to fit the entrance.

All it takes is switching a few parts around to fix it.

Here's how I did in the end:

1. Eduard instruction says: front door inner wall is 59-58 but should be 60-56 and inversely for the rear door on instructions

2. Eduard instruction says: front door is 69-67-66-23-22-74-53 but should be 69-67-66-23-22-[b]73-46[/b]

3. Your instruction says: rear door is 70-68-62-23-22-73-46 but should be 69-67-66-23-22-74-53

Again, that is how it was for me. I'm still scratching my head about this one wondering if I screwed up :)

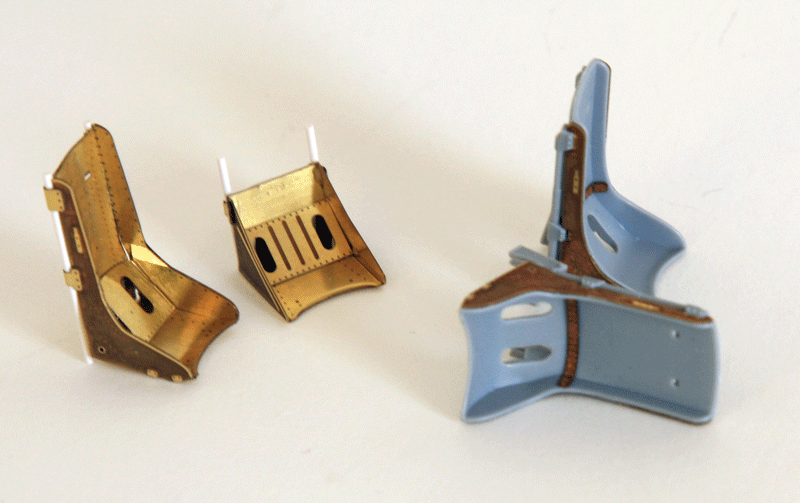

Seats

The crew of Maid in shade certainly earned the right to get comfortable flying the B-25 so I added some cushion in milliput on the kit's seats

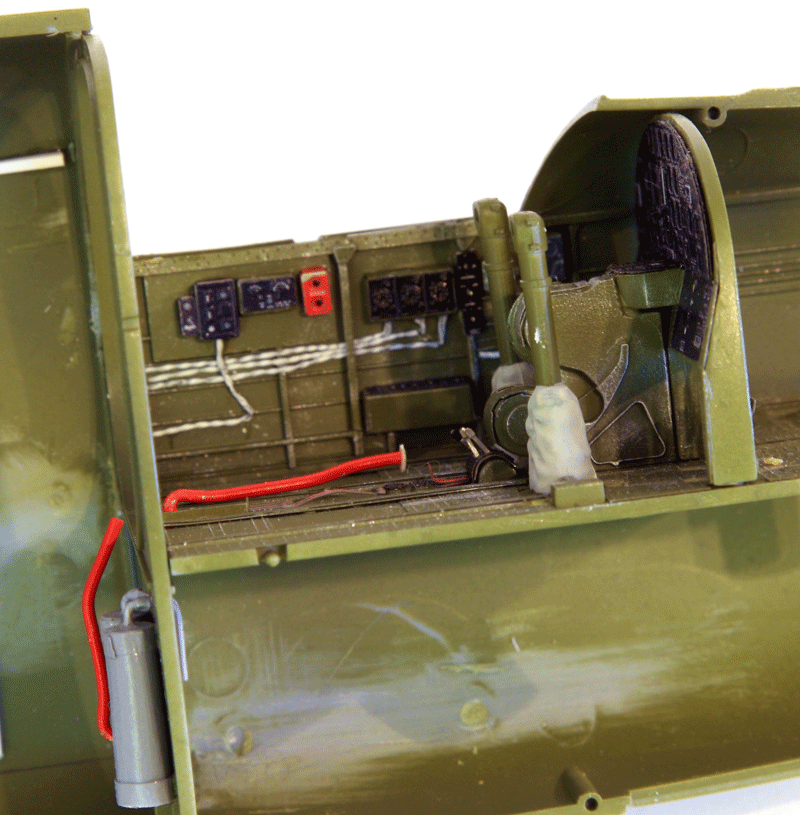

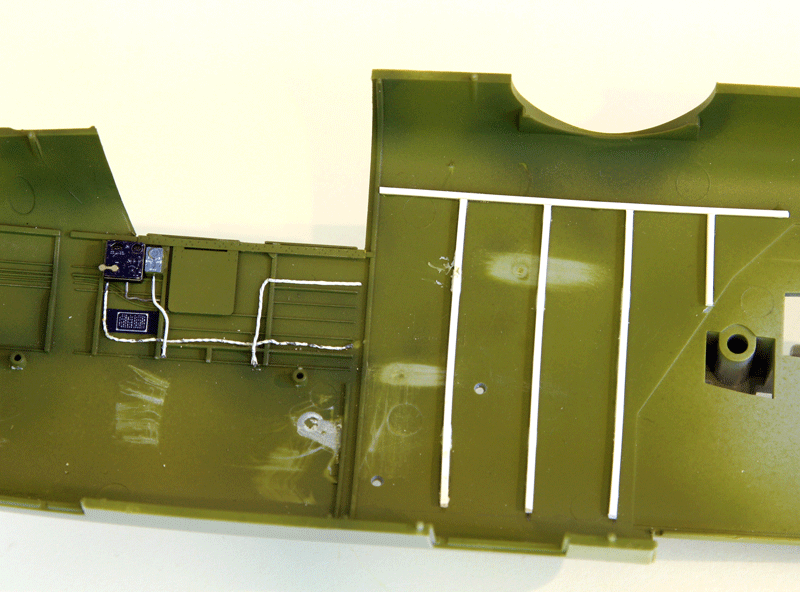

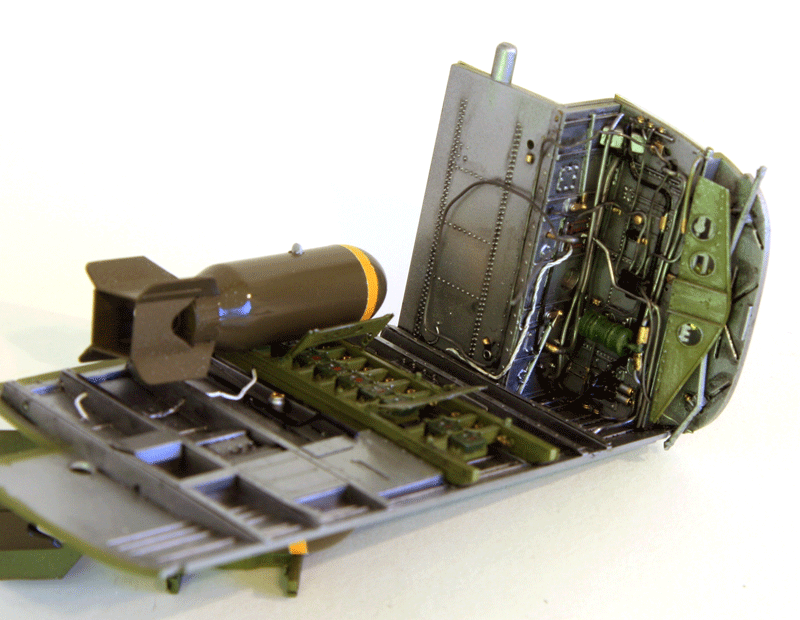

The hydraulic pump was redone with soldering wire - although I screwed up the end of it. the rest is basic painting, and Eduard PE's. weathering is WIP.

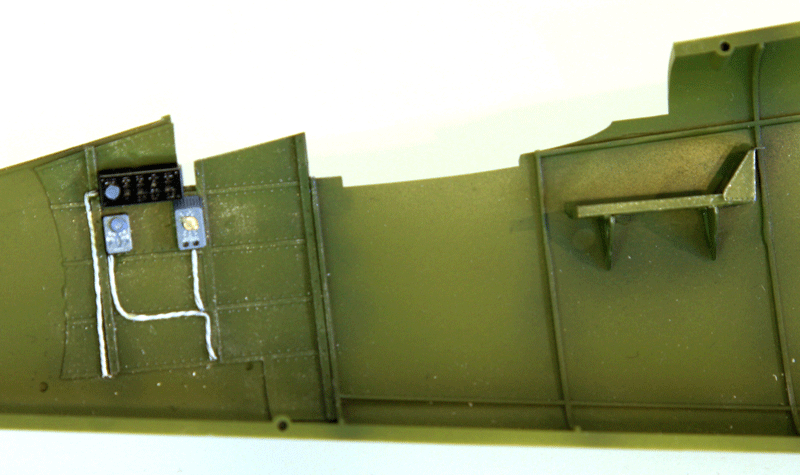

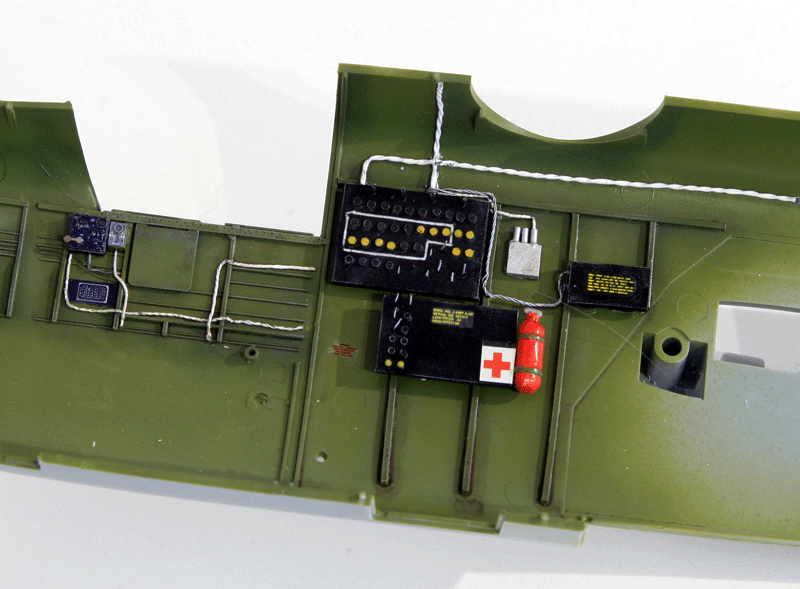

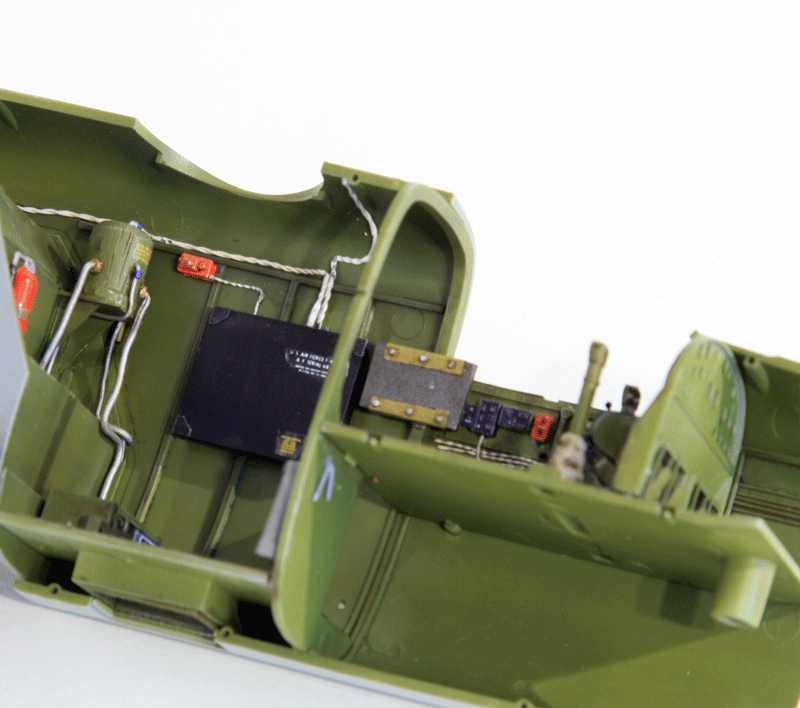

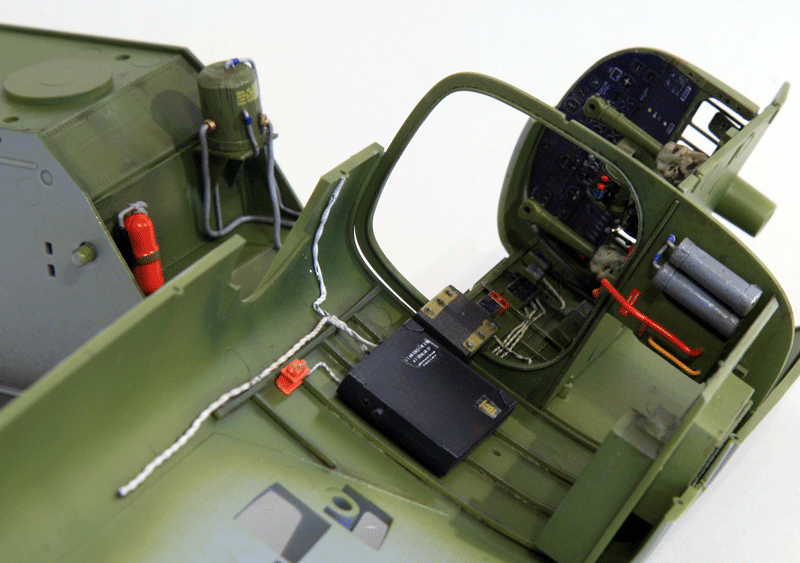

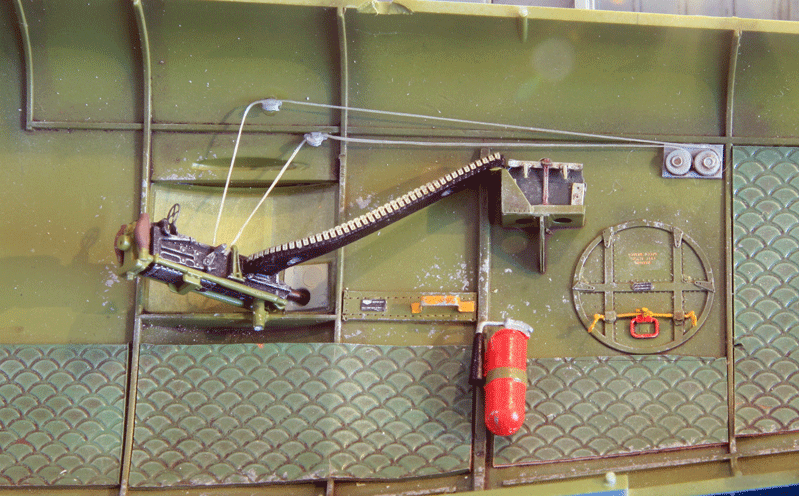

Right side wall populated with Eduard PE. I added some wires for the boxes.

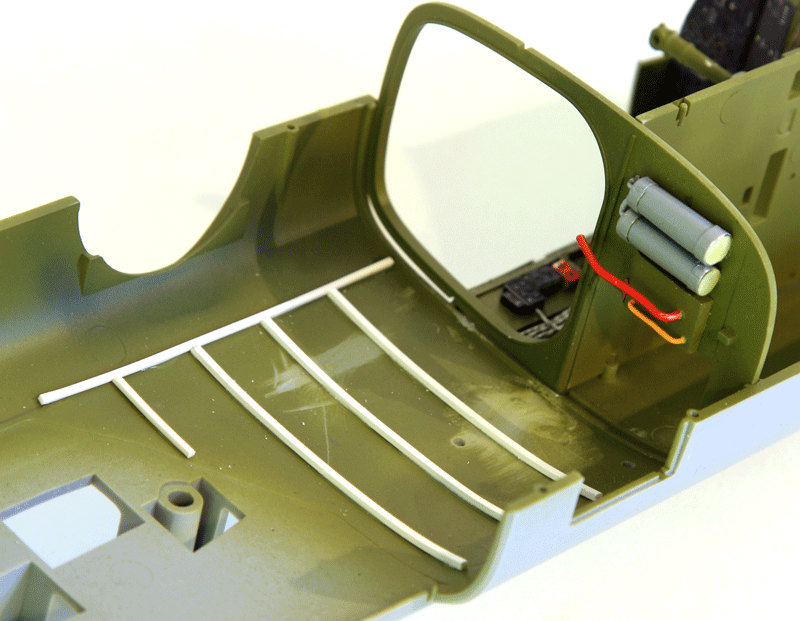

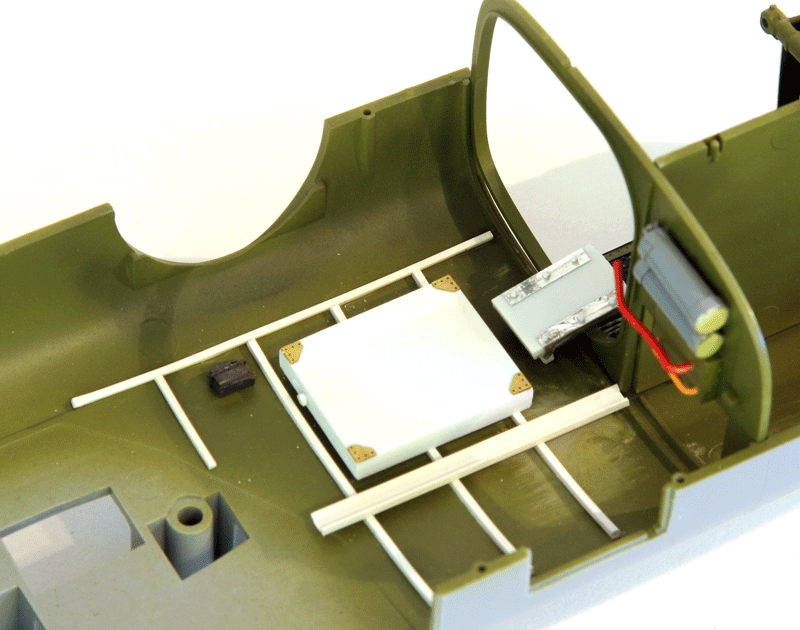

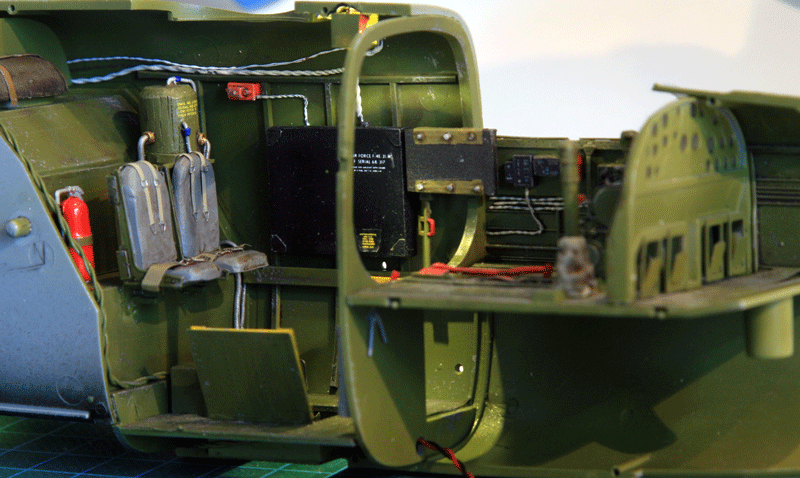

I also added some basic detailing in the top turret compartment behind the cockpit. The gear manual pump and some tanks.

There is no wall detail at all in the top turret compartment, I'm not going to remake the whole structure but I added some very basics ones so it looks at least like the rear compartment. That area will be heavily populated anyway with large boxes.

Maid in the Shade don't have the turret column installed and the turret is fixed in the rear position. so I will leave that out of the compartment.

Populating the top turret compartment:

The other side

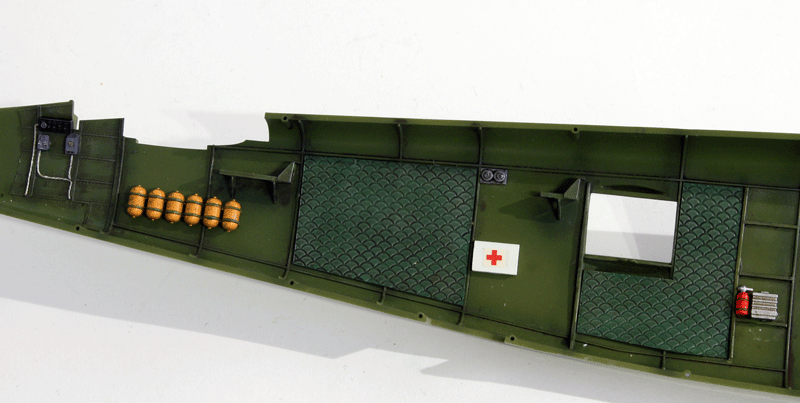

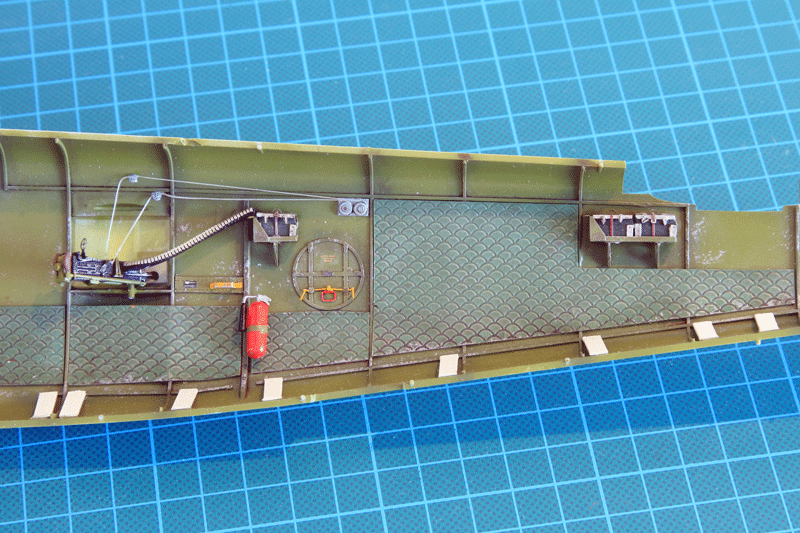

Some work on the rear with Eduard stuff:

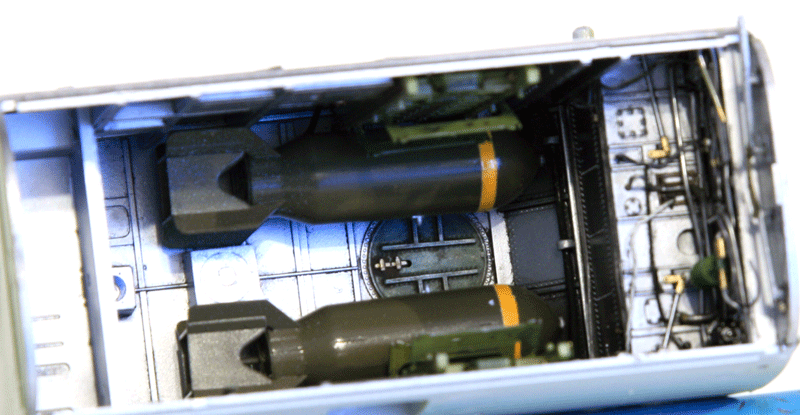

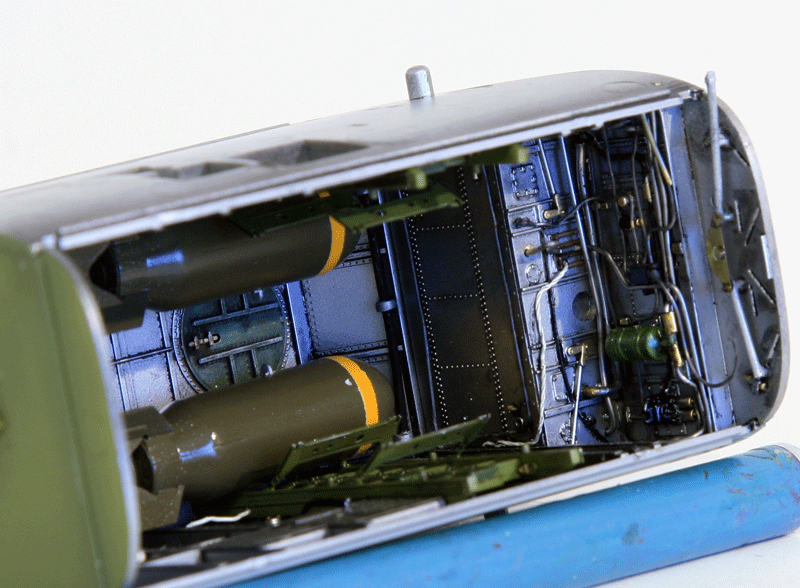

The bomb bay was painted in aluminum with details in interior green. More plumbing will be added as I close the bomb bay.

I decided to stick the two top bombs in there just to populate a bit the bay. Obviously these would be dummies :)

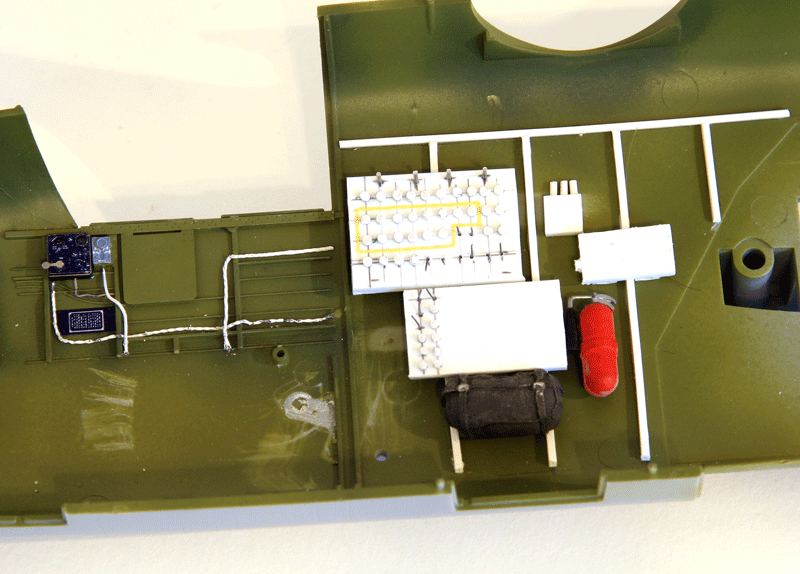

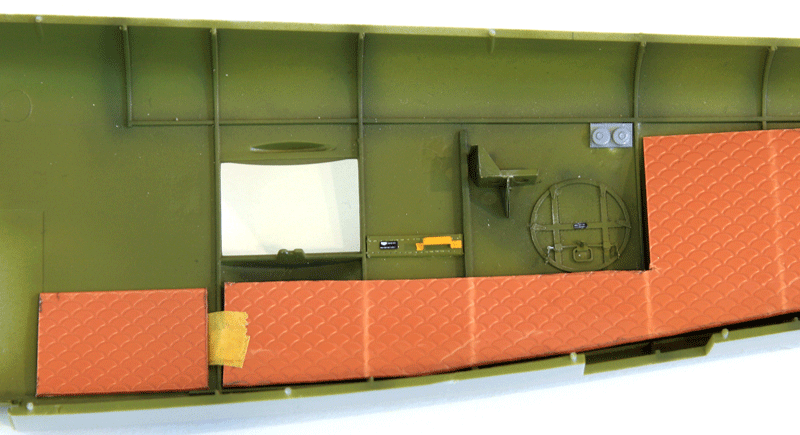

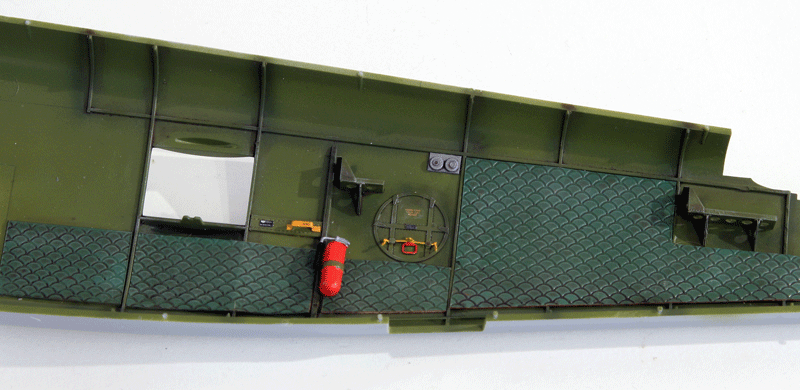

I sourced some textured plastic sheet to simulate the soundproof padding some civilian B-25 have on the inner fuselage walls. That's a great opportunity also to hide the lack of details in some part of the fuselage. The emergency exit door is not detailed inside the fuselage so I used the PE meant for the fuselage side bomb bay exit which is totally invisible after the fuselage is closed. It will be barely more visible on the fuselage side but it greatly populates that area.

I'll also detail the counterweight mechanism for the waist guns.

Some more paint and more goodies added. The other side received the same treatment

The front cabin was also painted and detailed a bit more.

Black boxes, fire extinguishers, wires, first aid kits...

An hydraulic tank was added on the bomb bay front wall in the top turret compartment.

I'll add some floor in the rear compartment. If it is not done and the rear access door is left open, the internal side wall of the door are just sticking out of nowhere. The plasticard floor will address that issue.

Thank you for the video Tom. It's one of the great things about this (very slow) build. Usually I hunt down pictures on the web but on this one I realized that if you look carefully at YouTube videos you find lots of interesting details for the interior of maid in the shade :)

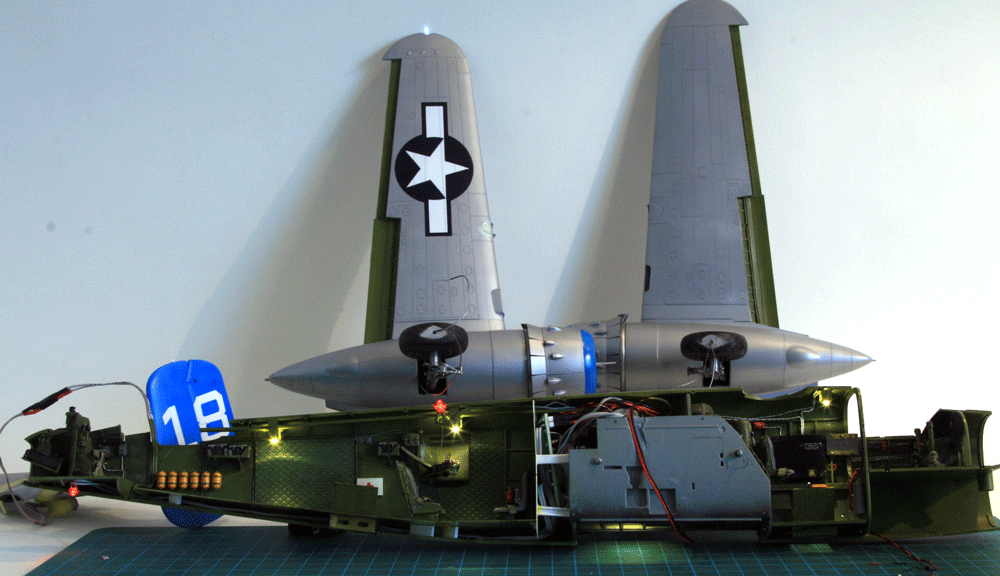

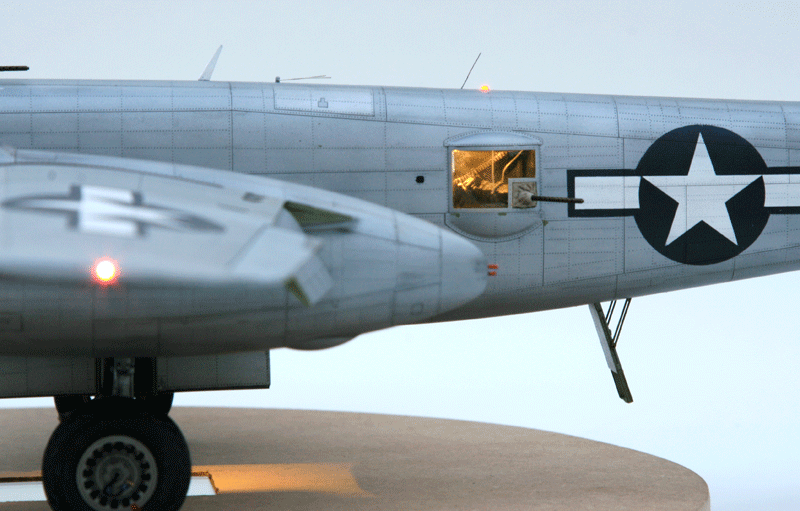

A few weeks ago I visited the IPMS Belgium annual contest and I met a very enthusiast guy who sells electronic components to light up our models. Here is their website.

I'm a flight Sim user and along the way I build my real size 1/1 F-16 cockpit which is full of electronics as well.

So I thought why not try to merge the two hobbies and put some electronics in that B-25.

It's not the first time I'm putting some leds or motor for props. The latest I did was a F4U-1D folding it's wing:

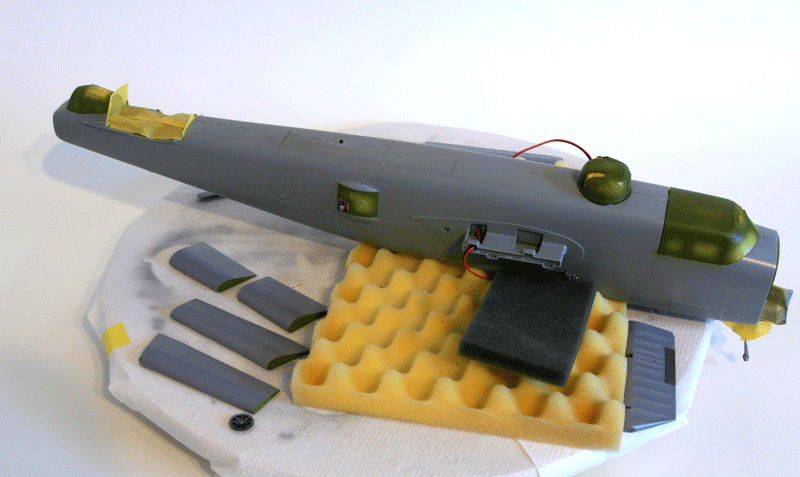

The build had to be stopped and thought over because obviously the challenge became more complicated and as I didn't want to make too many concessions to the electrical system.

I needed to carefully plan the next steps to ensure a seamless integration of the electronics into the model.

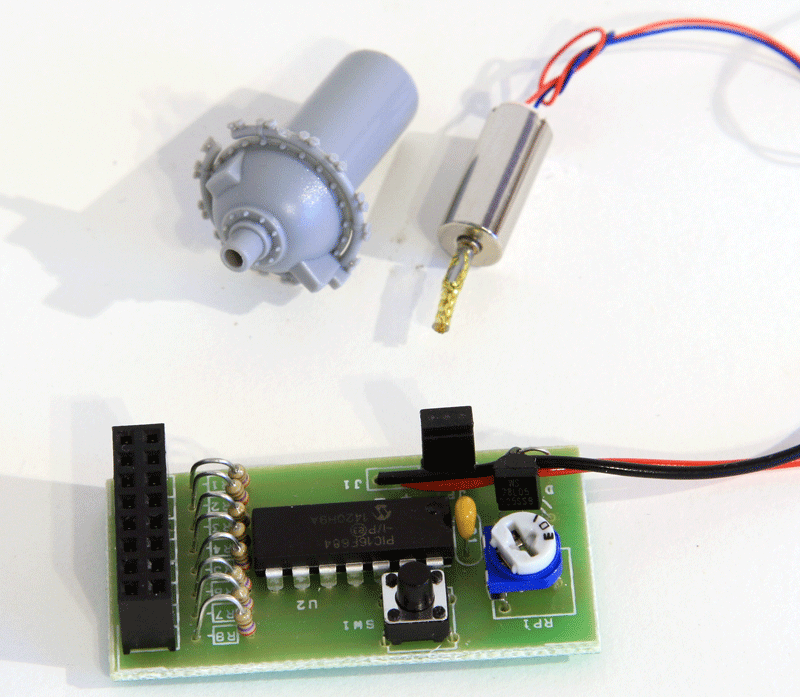

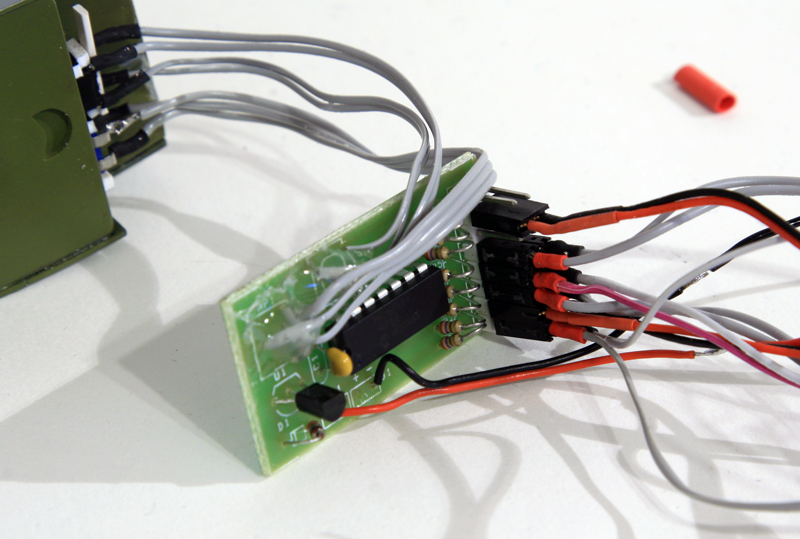

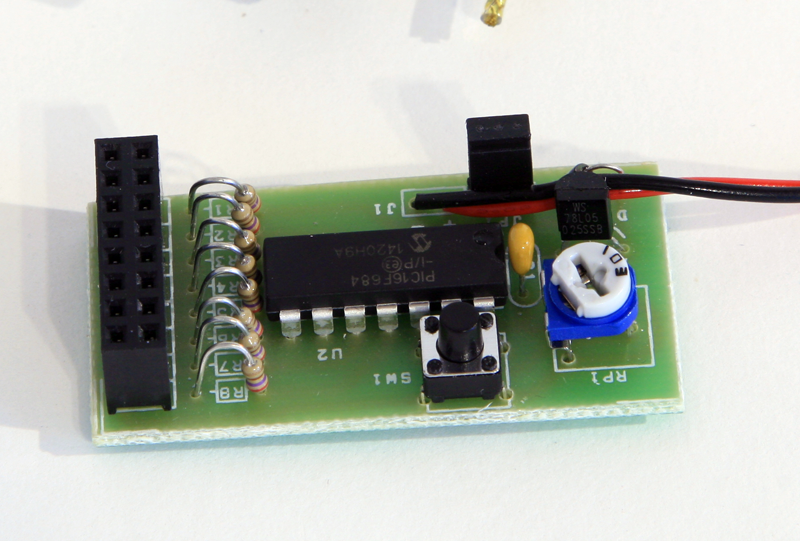

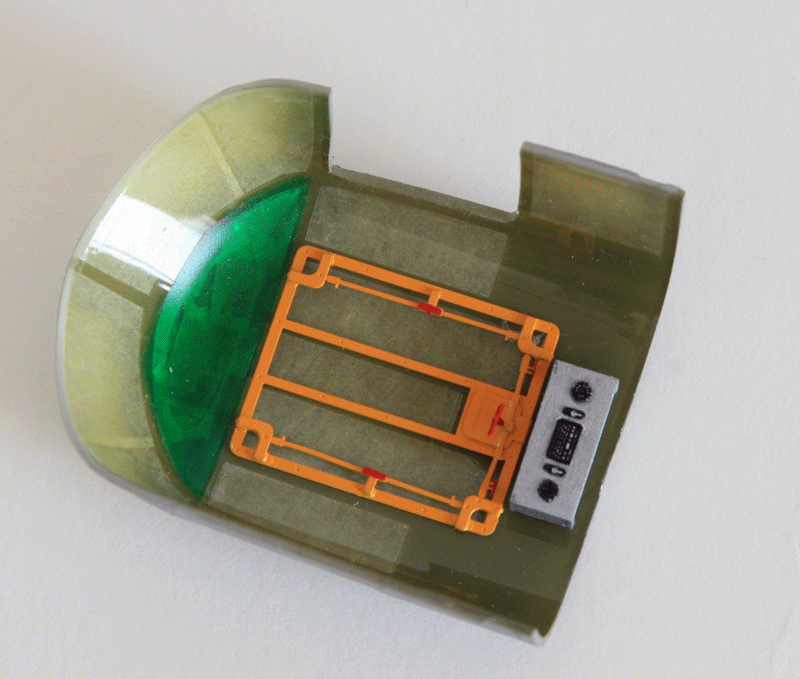

Putting leds is really not a problem and you don't really electronics boards to do that but this guy were selling a nice and easy to use PCB that allows 8 channels for lights settable to different phases & frequency flashing.

He also has different sized engines motors that are really suitable for props - although they turn a bit fast.

The Printed Circuit board has 8 channel output on which more than 1 led can be connected. A jumper to switch it on/off, a button to switch different flashing options for the channels and a pot to vary to frequency of each flash program.

I think there are about 16 programs predefined but I only need one.

My plan is to use 4-5 steady leds on 2 channels to light up the internal compartment, 1 channel with two leds for the left wing (Landing light and wingtip light, both steady). The same configuration for the right wing and a flashing channels for the AC lights:

One on top of the fuselage above the waist station. One below the tail (opposite phase) and the last one on the left tail.

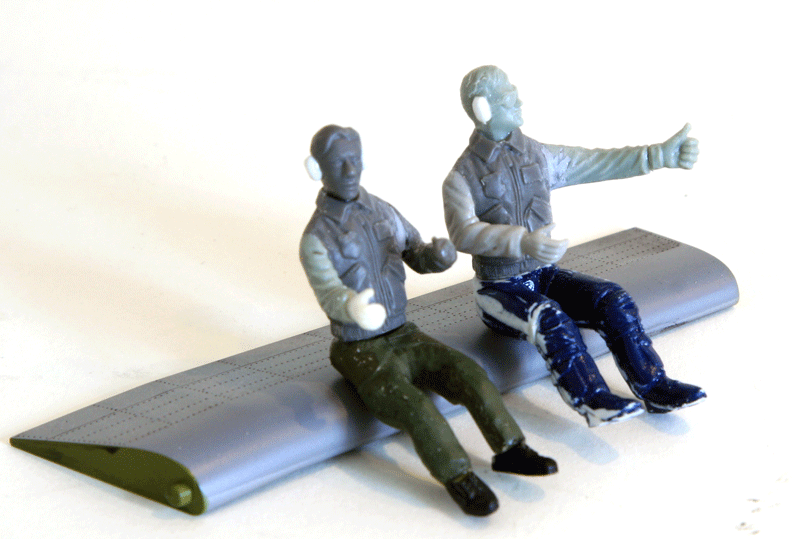

Of course with all the lights on, the engines need to turn and pilots need to be in the cockpit - finding adequate seating civilian pilots with David Clark headset is the real challenge now :)

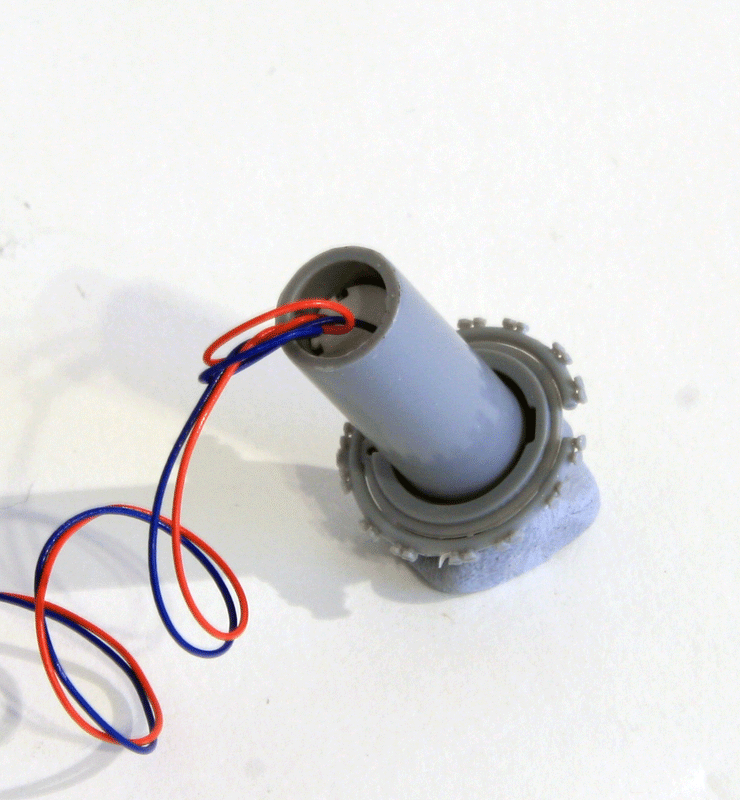

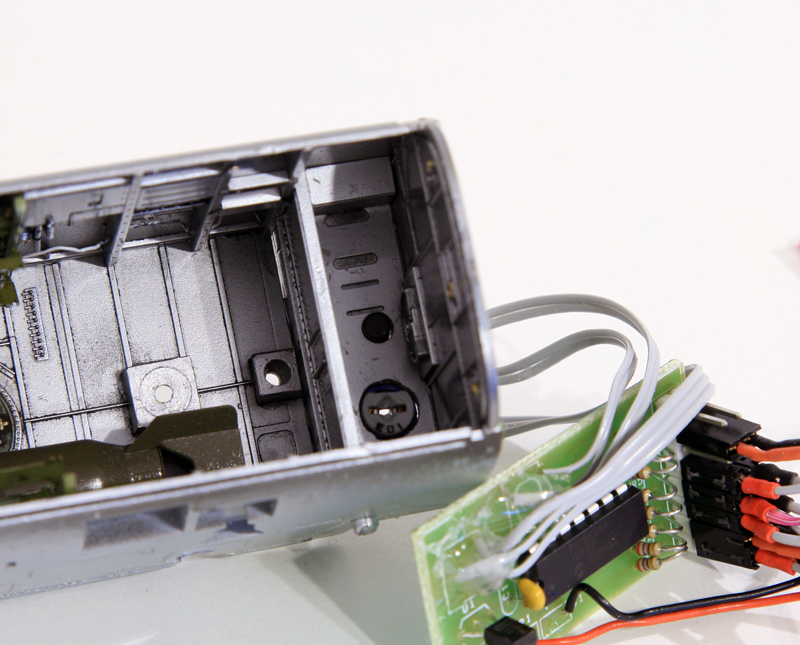

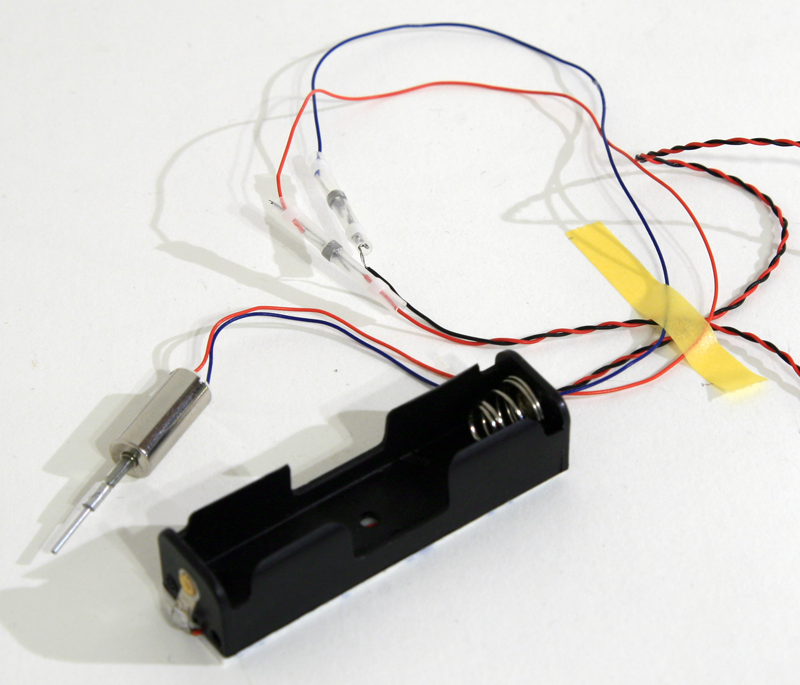

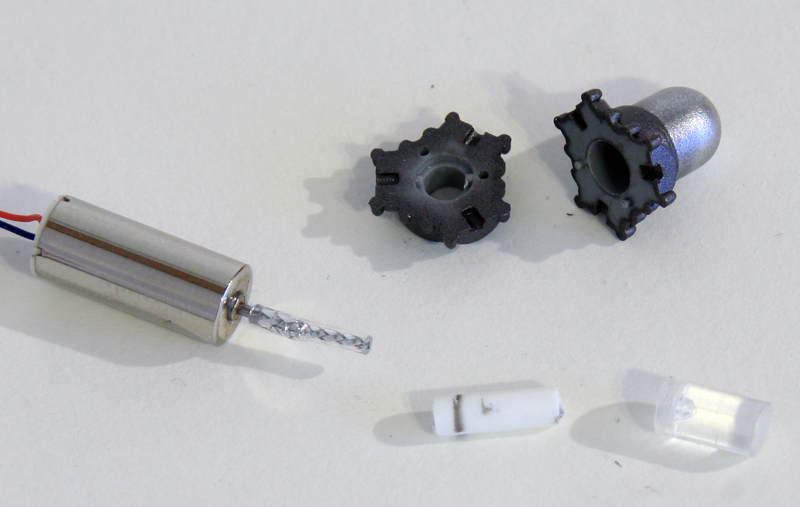

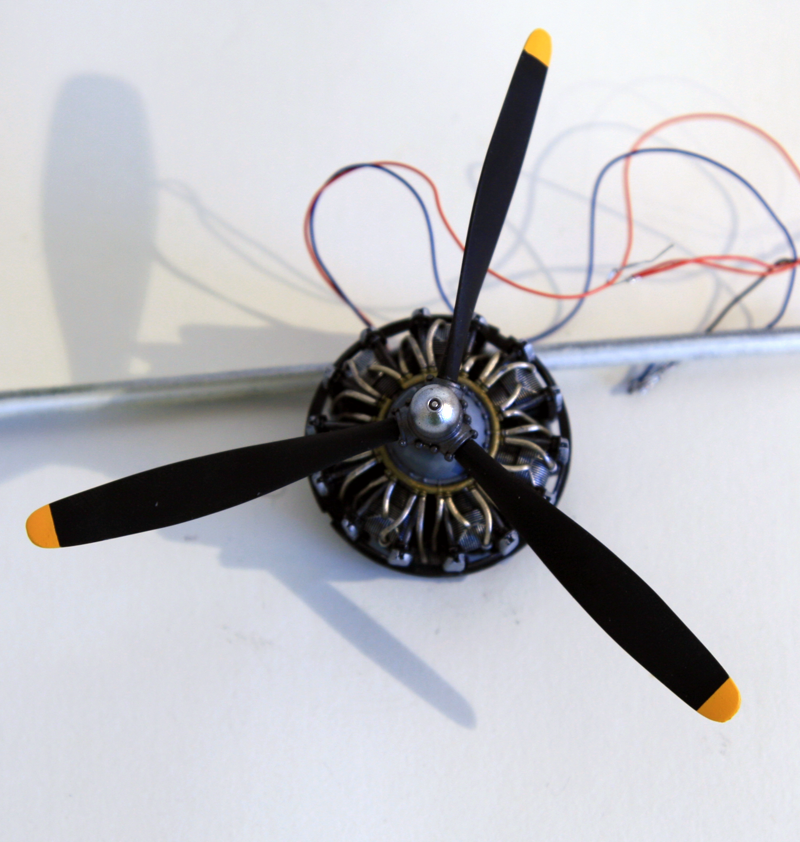

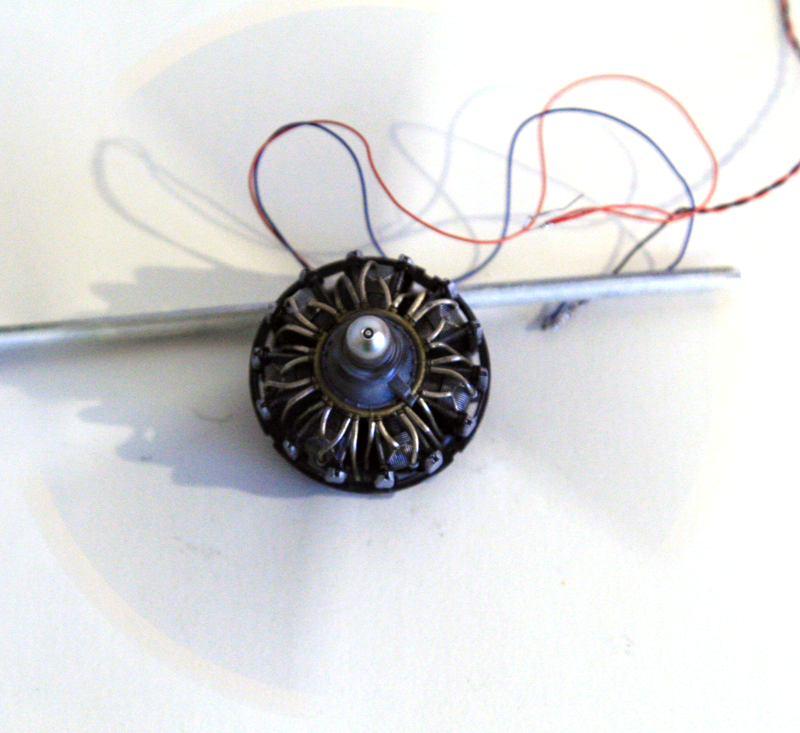

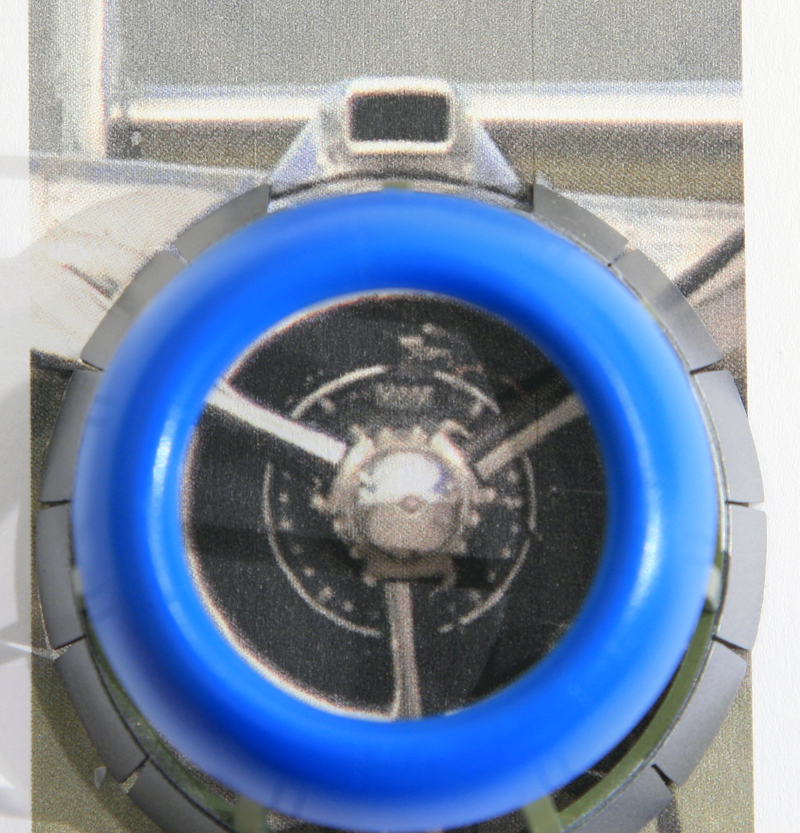

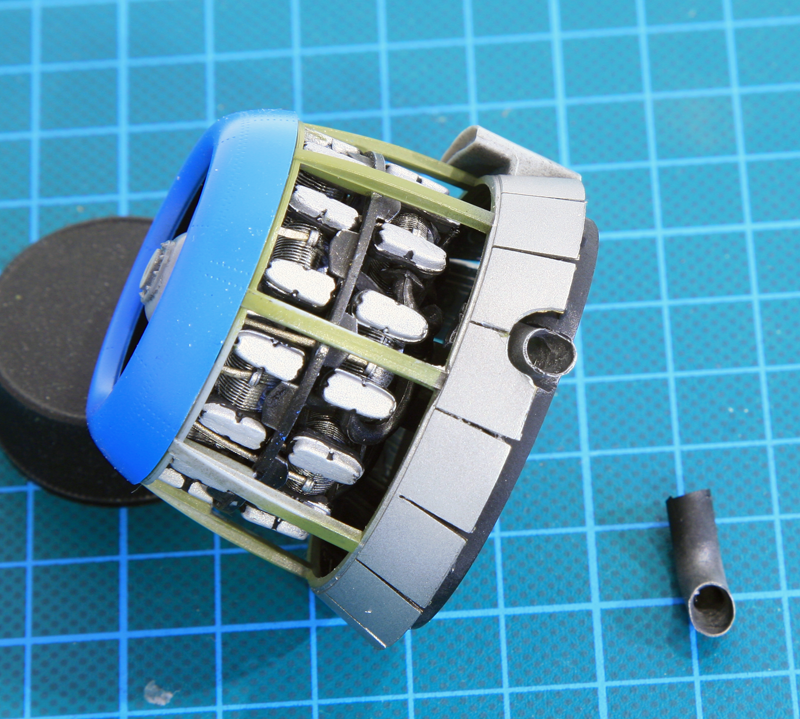

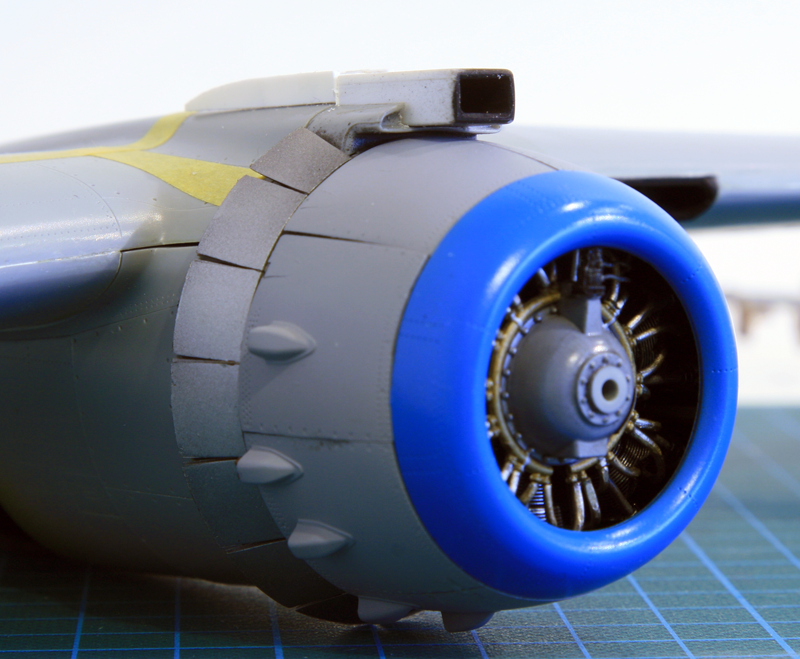

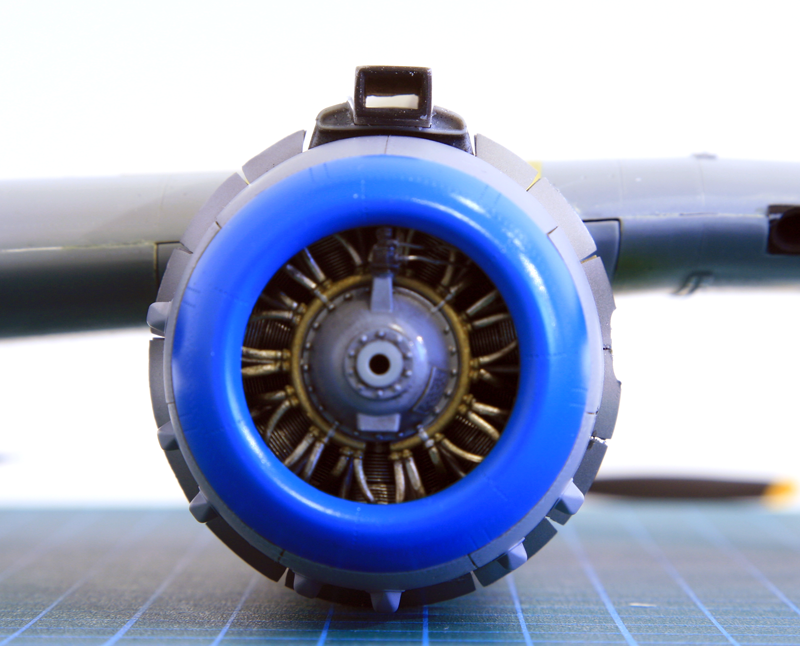

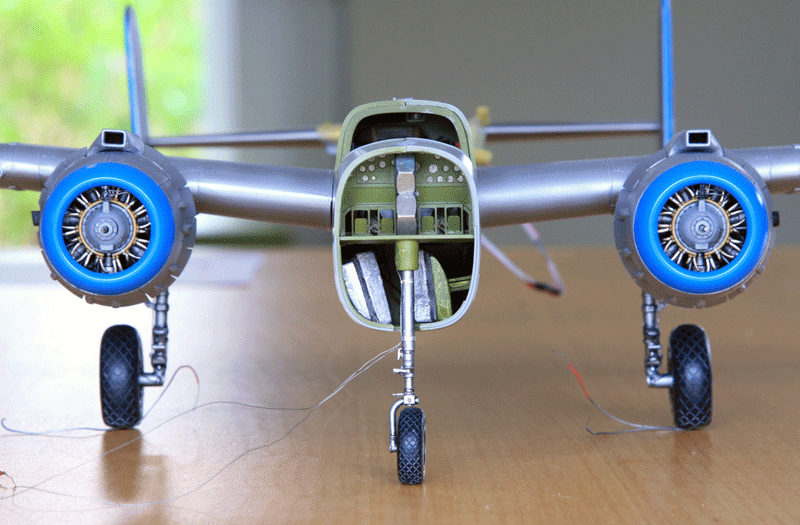

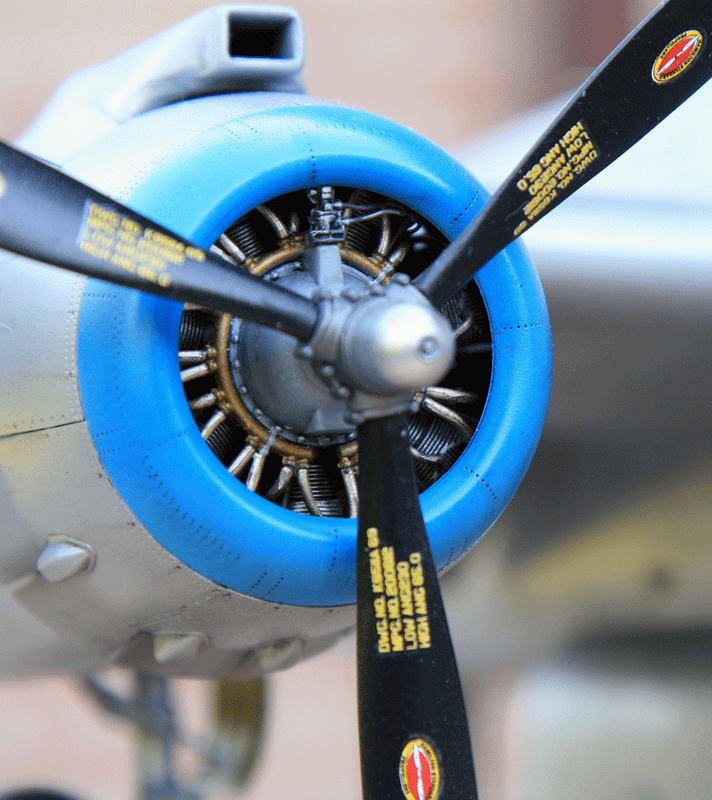

The smashing discovery is that one of the engine model Richard was selling is tailor made for the HK B-25!!

The kit part has a hollow cylinder behind the crank case in which the small engine is fitting perfectly. I couldn't believe it.

Look at that fit !! I planned to use AMS crank cases but having such a nice fit and ease of installation will force me to compromise and use the kit's part rather than the better AMS resin part.

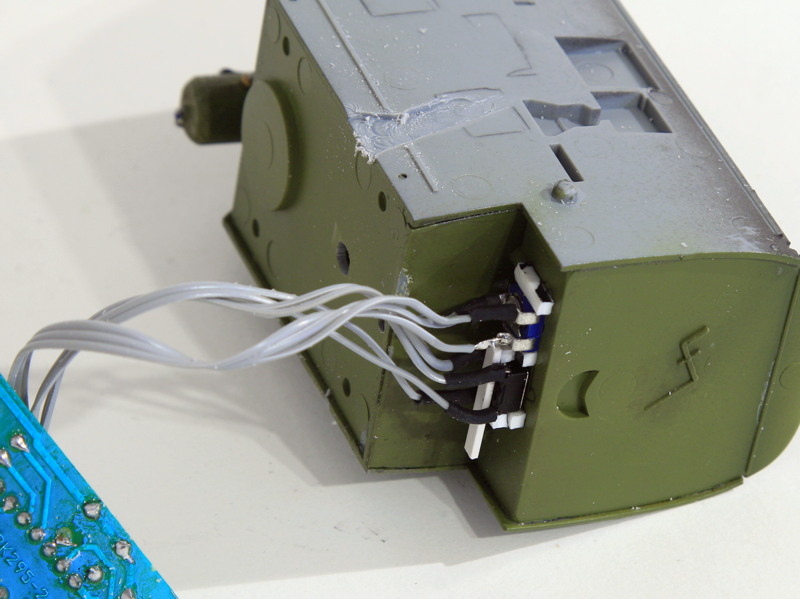

I also wanted to keep the button and the pot to set the programs and the flashing frequency. So I unsoldered both of them and soldered them to wires rather than straight on the PCB. The next logical thing was to find a suitable hidden place for both component:

The bomb bay once again provided the obvious answer. The rear part of the Bomb bay where HK has a PE plate installed provided a flat surface big enough for both the electronic parts. Holes were made and the components attached in place on the outside walls of the bomb bay.

Now whatever happens I can access the PCB programs option with a small screwdriver in the bomb bay. I also shorted the jumper so the system is always ON and it can't be turned off accidentally. I wanted to avoid that as I wouldn't be able to access the PCB once the fuselage is closed.

I will rather place a switch on the main wires later on.

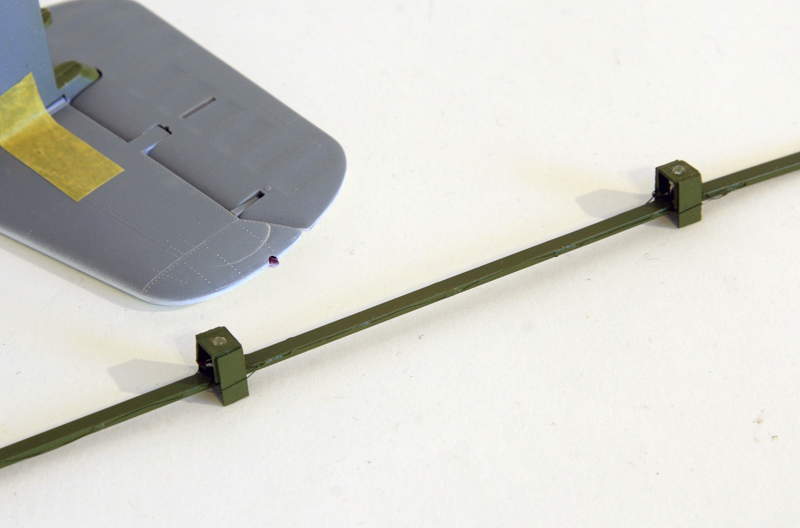

There is a light bulb in the bomb bay, one of the internal light led will go in there as well. The front compartment behind the cockpit and the nose section will have their own led as well. The rear compartment will get two leds. I built a rail to support the wires and the led that will be glued in place on top of the compartment. The rail will also hide the wires for the top red anti collision lights that will be placed on top of the waist station.

The left tail has what I guess is a light as well, but I wasn't able to confirm that yet. Anyway, it's been placed inside the left tail as well and is ready.It's already masked with maskol for the first paint tests

Putting electronics into a plastic model is challenging and a real danger for the build completion. The chances of getting tired of the problems and sending the unfinished kit to the infamous shelf of doom are higher than with a normal kit. Luckily the electronics in this case are rather easy thanks to MagicScaleModeling who designed the board.

They designed it on the principles that modelers are experienced with glue, mastic and sanding paper and more often than not housecleaning products :) but not especially with a soldering iron.

So they offer the PCB with all the goodies you need for your project with a minimum of hassle.

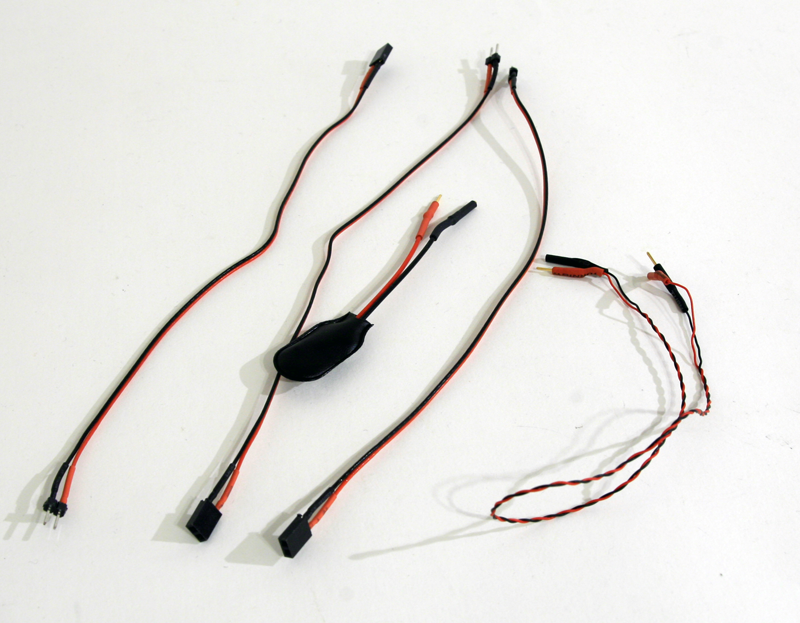

- The wires with male and female connectors soldered at variable length, the 9V power supply or the battery connector. All provided with quick foolproof connectors:

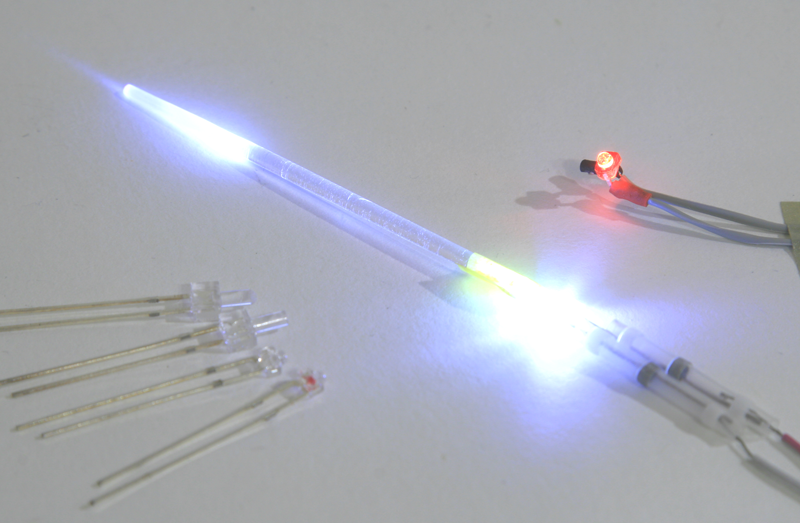

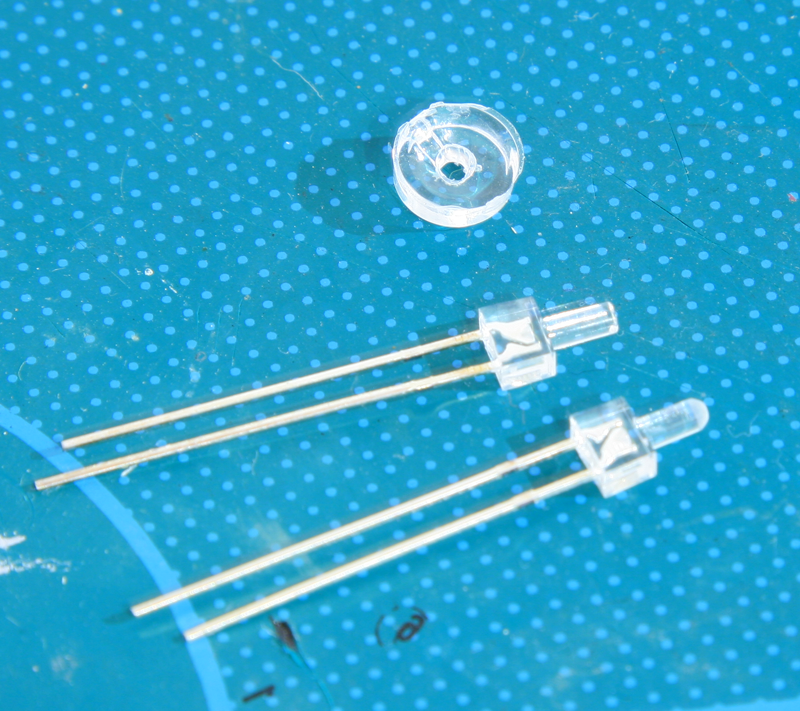

- the leds (and they have plenty different type very suitable for modeling project).

Cold white, Warm white, Coloured (although it's not ideal, more on that later) flat top, rounded top, long short, ...

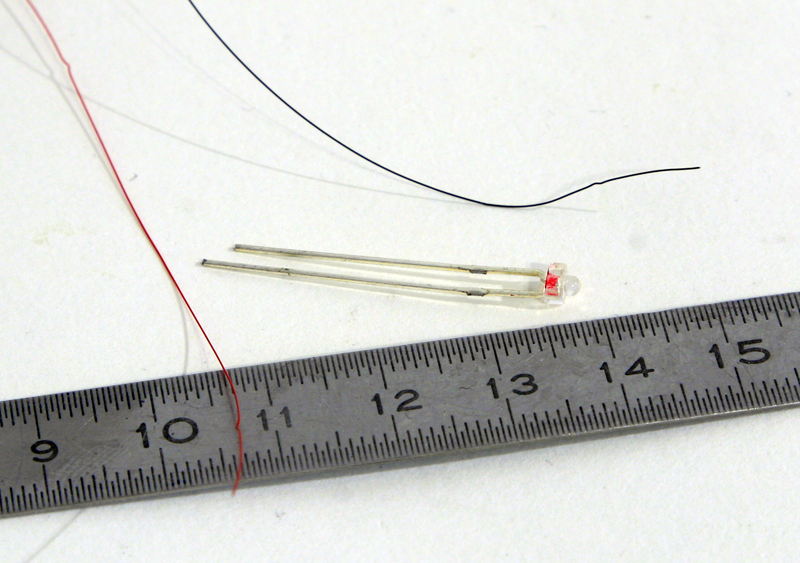

All the leds are the smallest possible, the one above are less than 2 mm.

We could also use SMD (Surface Mounted Leds) which are even smaller but very bright and IMHO way too bright for the scale effect.

The long flat top leds can be sanded to any shape.

The small round top are ideal for compartment lights

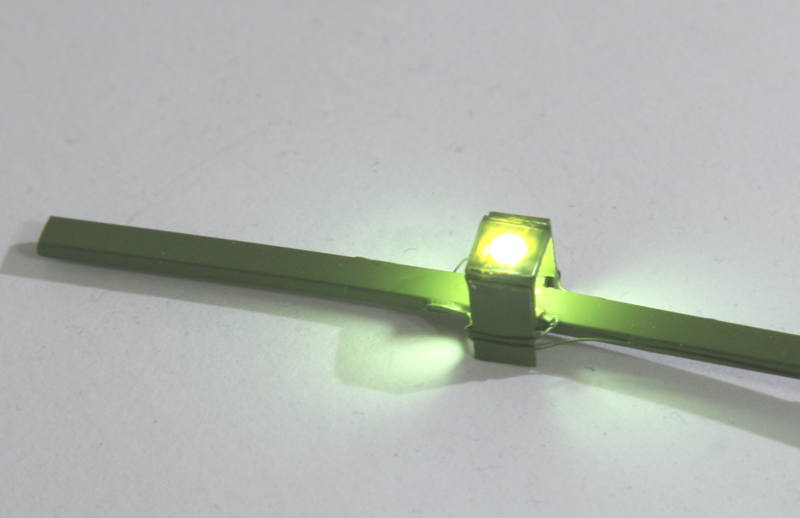

The long flat faces are ideal for optic fiber effects (more on that later)

Coloured leds have different voltage and their intensity from one colour to another is variable. So I always prefer to use all white leds (cold and warm depending of the application) and paint the leds with transparent tamiya paint myself. That way I can keep the led brightness more or less constant.

Usually leds are too bright for the scale effect, so I tend to use the fibre optic effect as illustrated in the above picture. The flat face leds are ideal for that as it's very easy to find any transparent plastic rod of about the same diameter as the led and tape it to the top of the led. As you can see on the above picture the light pass through the plastic tube but doesn't shine through unless you sand the tube. That's perfect when you want to add lights in tiny spots where the led is still too big to be inserted (like wingtips for instance).

You sand the tube to the desired shape and place the led further down in the wing where you have enough room.

Beside the fitting issue it also decrease the led brightness which is great for the scale effect. Wingtips lights aren't usually very bright and have to be toned down for the scale effect.

The innards of the plastic part might need to be painted black to offer a further opaque coat to prevent the light to shine through the plastic - especially if the plastic was sanded thin.

The engine kit is provided with one motor, one battery holder and two solder free connectors.

IMHO there are only two basic knowledge's you'll need to know to add electronics in your models.

- The first is a limited knowledge about soldering. I personally don't believe it's possible to light a model without soldering a few wires. Although ready made connectors may be used they are huge and can be used only where plenty of room is available and they can remain hidden. So inevitably soldering skills will be required. Soldering is not complicated as for most of the tasks we are accustomed to it just requires patience, experience. and often a third hand. :)

- The second is knowledge of polarity. +/-. That's easy. You know the red wires and the black wires :)

The only thing tricky is that leds are directional. They let the current pass through only in one direction. So all there is to know really is which is the + and - on the led.

The + is called Anode and is the long leg of the led. (some leds also have a flat on the + side)

The - is the cathode and is the short leg of the led

From there all you need to know is to solder the long leg of the led to the red wire and the short leg to the black wire. And then cut the legs. If you cut the legs before soldering you won't know which is + and which is -. Well there are other ways but I wanted to keep it basic :)

So managing the electronic is very simple. What is a bit more complicated is to ensure that the electronic parts are as hidden as possible in the model.

Electronics components are huge in our scale - even 1/32, cables are way too thick to be left visible, leds might be too bright and too big as well.

the most challenging to me at least is the hide the cables. A regular electronic wire (I use IDE cable from computer) is 1mm diameter. In 1/32 scale that's a cable of 3.2 cm. Way too big for cables running alongside the compartment walls.

Luckily Magic Scale modeling made me discover these tiny cables:

They are 0.1mm diameter red and black and insulated! That means you can twist them together and use them as we would use copper wires to add wiring to our models, no risk of electronic short.

To solder them to leds you need to heat the wire first to melt the insulation. Then it solders like any other wire. They are perfect for our applications.

That's what I use when I can't make the cables invisible.

In some cases hiding the leds will require creativity. To light up the rear compartment I created a rail in plasticard. The rail is not in the real B-25 but that's an artistic licence I took to solve one of the problem.

Internal floodlight is perfectly made in scale with low warm white lights with short & rounded faces. They are not yellow but not too blue either. They are just perfect for flood lighting.

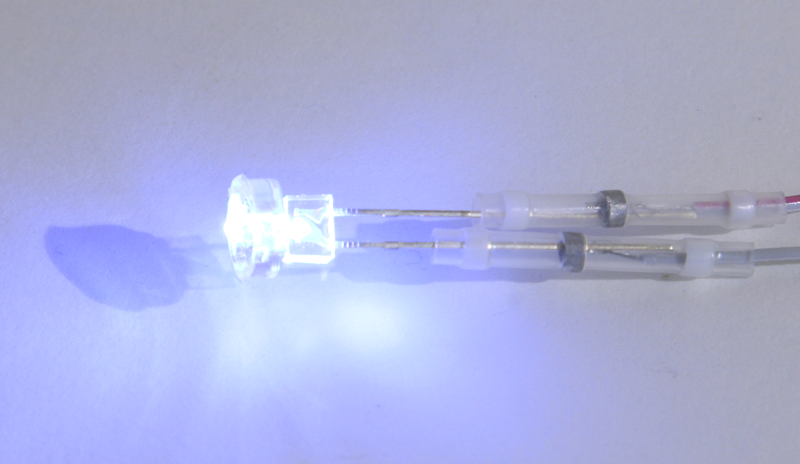

In other cases, it's dead easy to do:

Let's take the wing landing light of the B-25. the kit has a plastic part for the spot embedded in the wing.

I'll use a 1.8mm white led long and flat face and round the face myself with a small file until I have a nice bulb shape.

Next I'll drill 1.6mm through the transparent plastic part and force the led Inside the kit part

and light it up

All that's needed now is to solder the led and connect it to the CB in the fuselage. It's a tad bright, but landing lights are supposed to be bright. I may try to dim it a bit though...

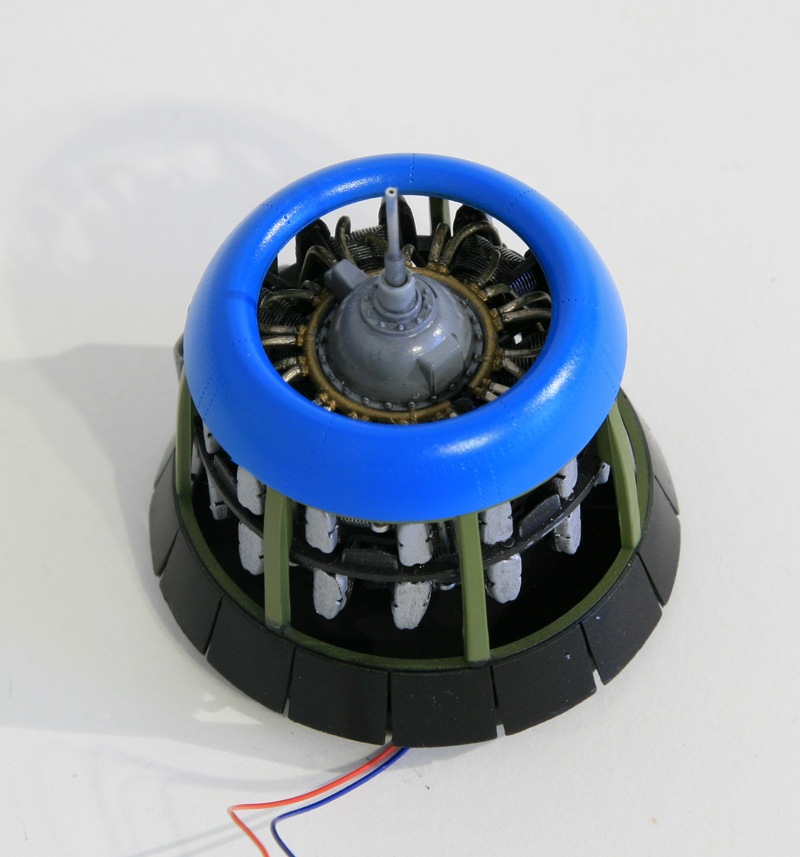

Let's do an engine test run:

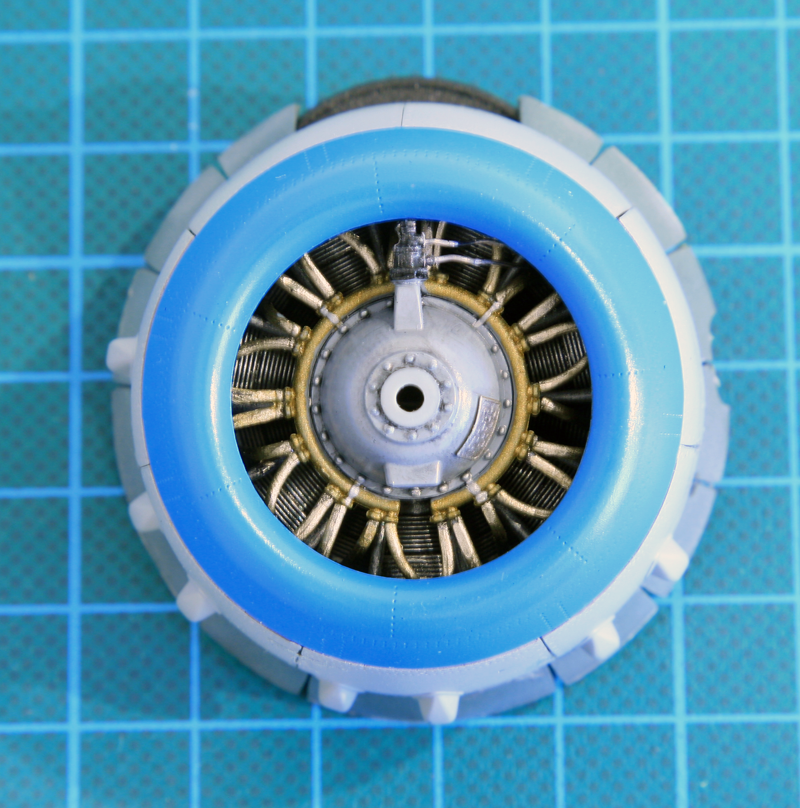

The engines are a pleasure to work on. The cylinders are painted aluminium's and given a wash of black oil. Most of the structure is painted black and slightly dry brushed in aluminum's. I also used titanium gold paint and the crank case is painted H307

I won't display any open panels so most of it will be invisible.

For that reason many of the PE parts for the engines from Eduard Big Ed kit won't be used.

The front face will get some more detailing.

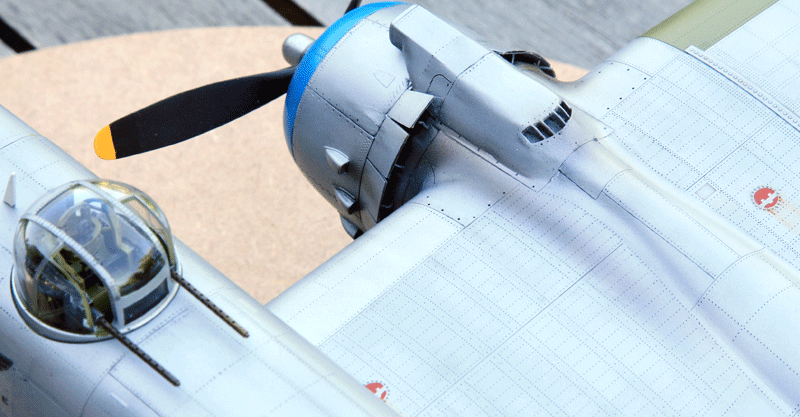

As I said before I unfortunately won't use the AMS crank case because the Magic Scale Modeling motors fit to nicely the kit parts.

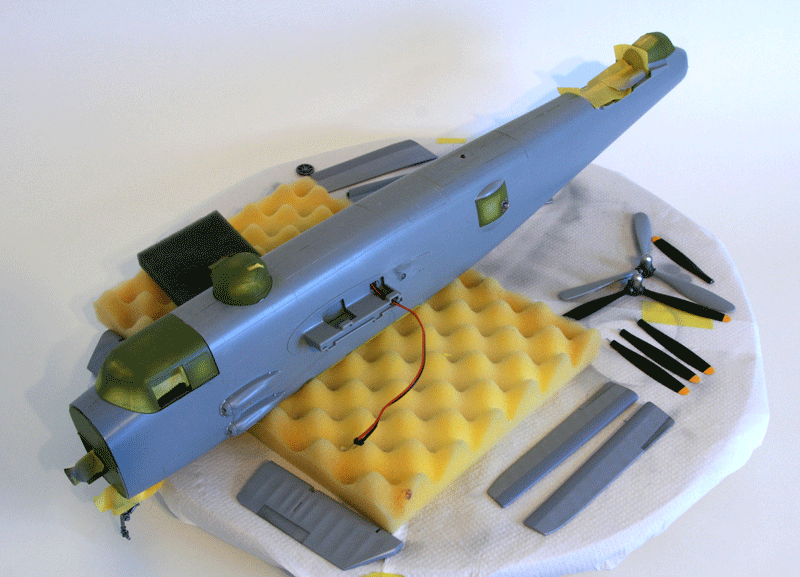

The props need some work to be used with the motor.

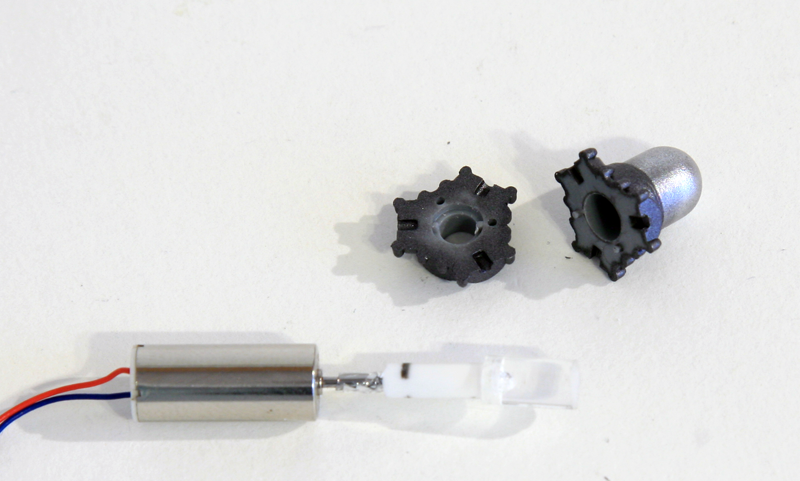

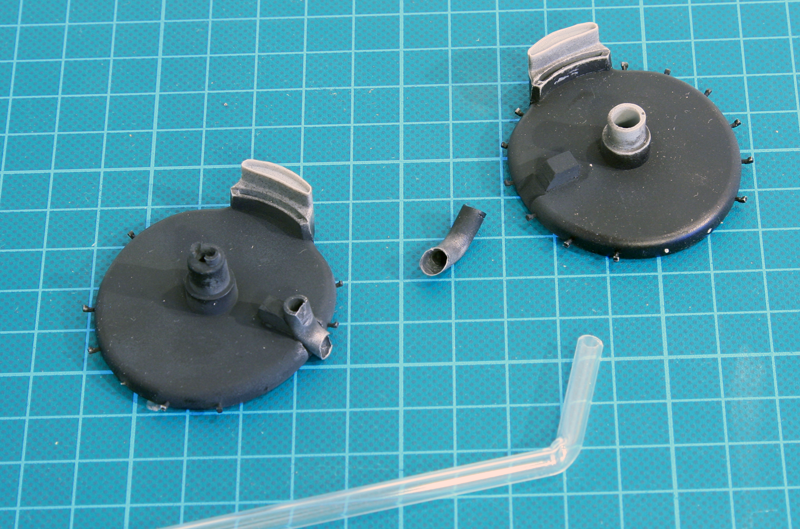

A transparent rod was cut to size and will be inserted into the propeller dome. The smaller white rod sits inside the transparent bigger rod.

The metal extended motor rod will go through both of them to ensure a good grip during rotation.

The white rod is cut smooth behind the prop governor. Normally the prop sits on the bit extended from the crank case but the fit is too tight and I am concerned it would prevent the props to turn freely and burn the motor. So I will cut the kit's crank case smooth to prevent that.

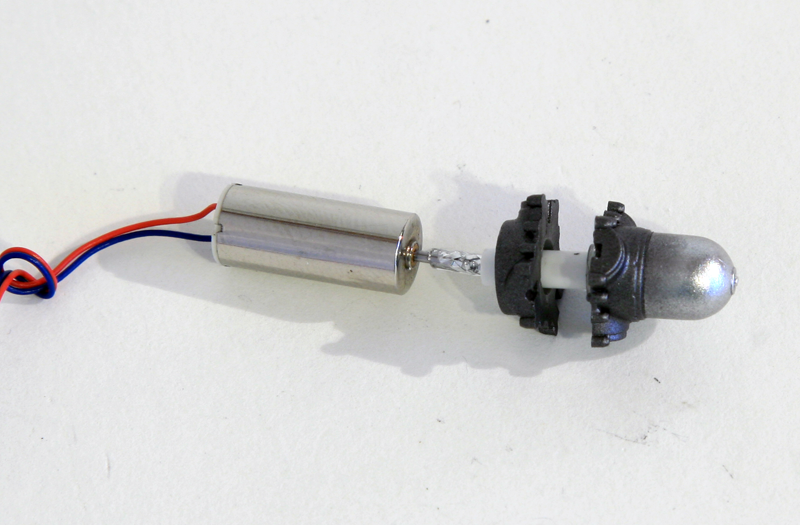

The motor sits inside the engine and the rod has been extended a bit with 1mm metal rod.

Kit's props are quite fat compared to the nice AMS resin replacement. The only advantages of the kit's part is that they sit perfectly well in he governor with the specific shaped holes.

AMS replacement pins are too thick. I'll cut them and replace them with small metal rods.

The prop is inserted on it's motor axis

And the motor is turned On. It turns with a minimum of vibrations. Concept is validated and I can move on.

It's now about time we get some paint on that model and get back to old fashioned modelism :)

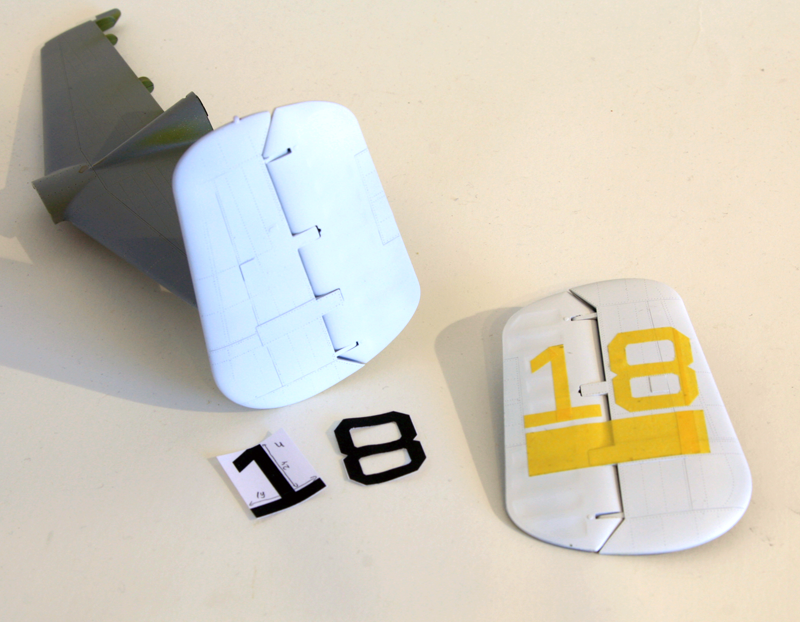

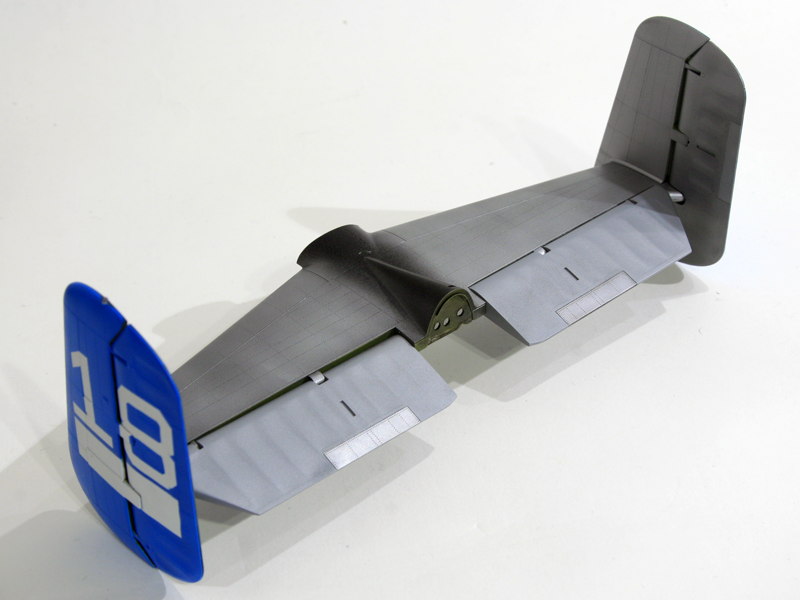

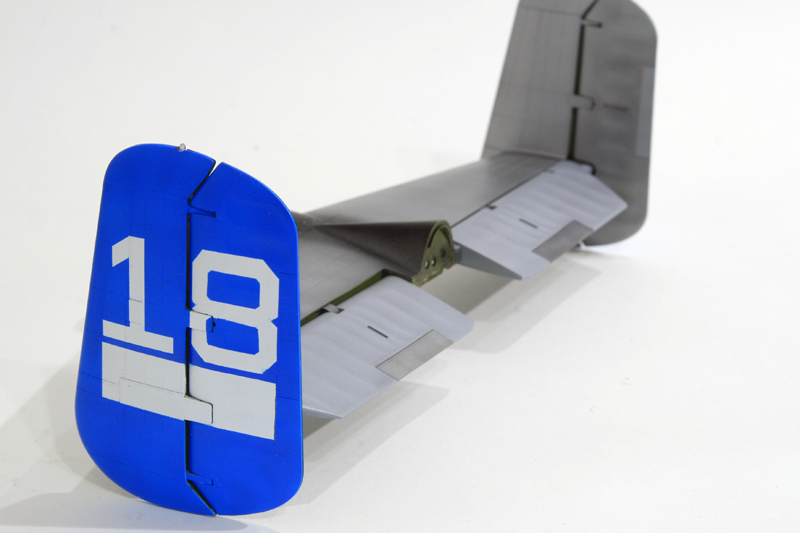

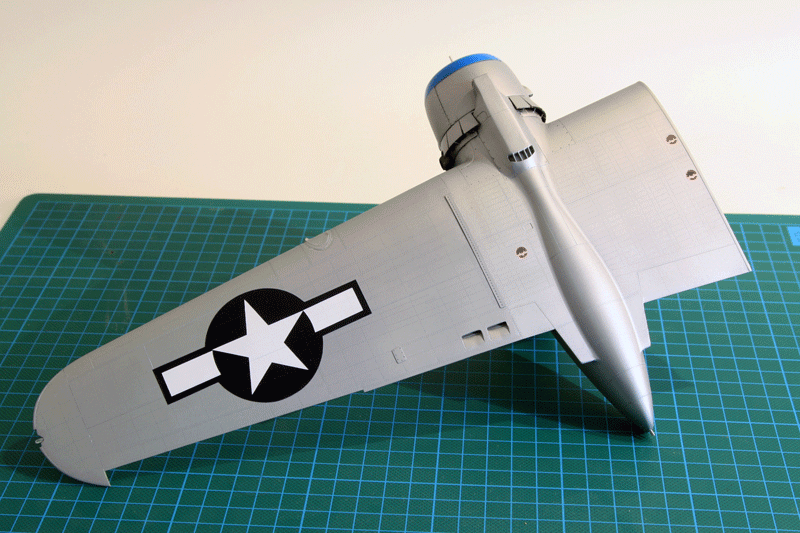

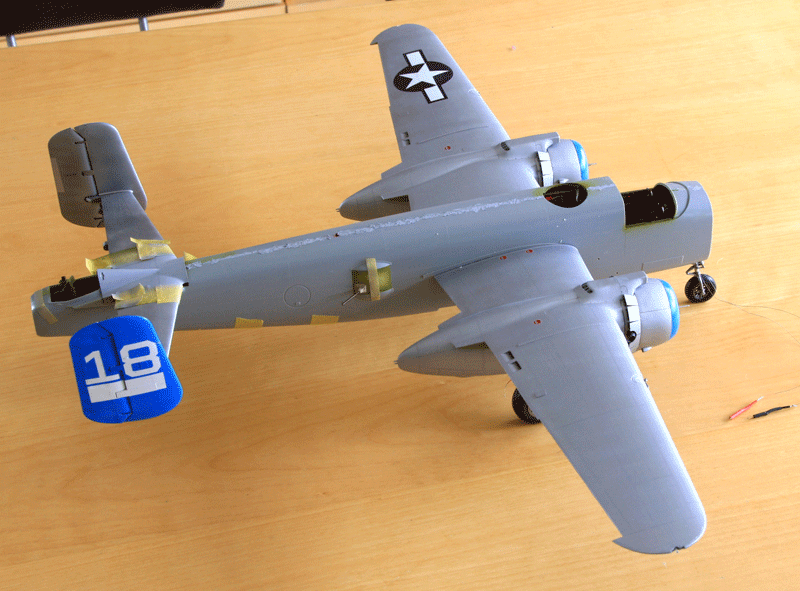

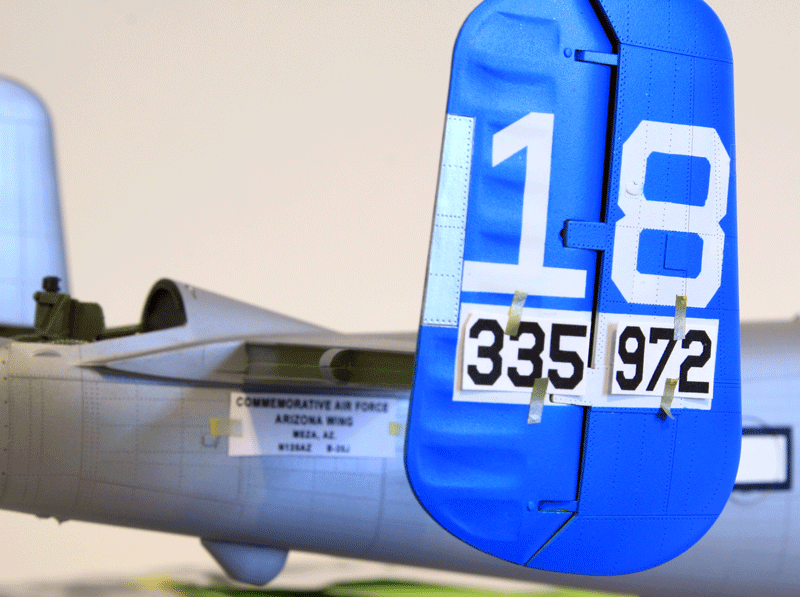

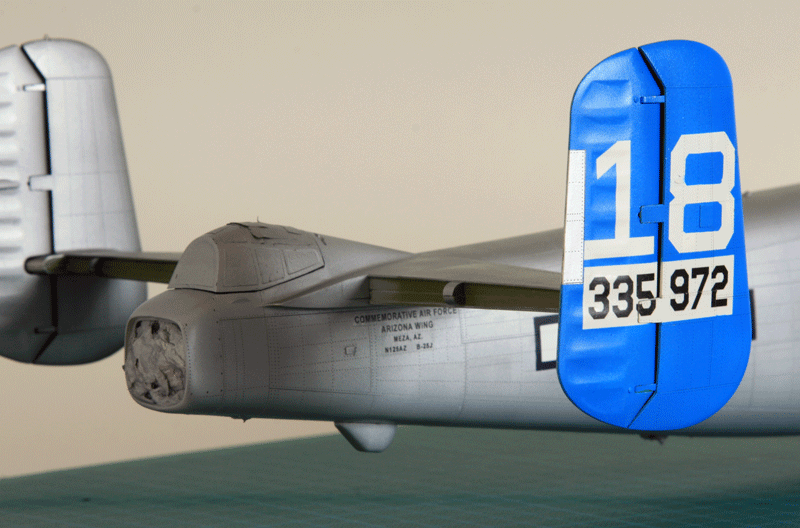

First the tails. Since I will do most of my decals i will spare me the trouble for the big ones and paint them straight on the model.

The easiest will be the big 18 number on both tails:

I started painting the tail in white, then masked the numbers and the white rectangle for the decal serials and then sprayed blue

Next was to try out some alclad tones on the model. Unlike some civilian restored B-25 Maid in the shade isn't very shiny. Matter of fact it's pretty dull.

I first tried airframe aluminum's thinking it was less shiny than aluminum's but soon realized that it is shinier and darker than aluminum's. not good for this project.

I then tried semi mate aluminum's and that was about the colour I wanted to have.

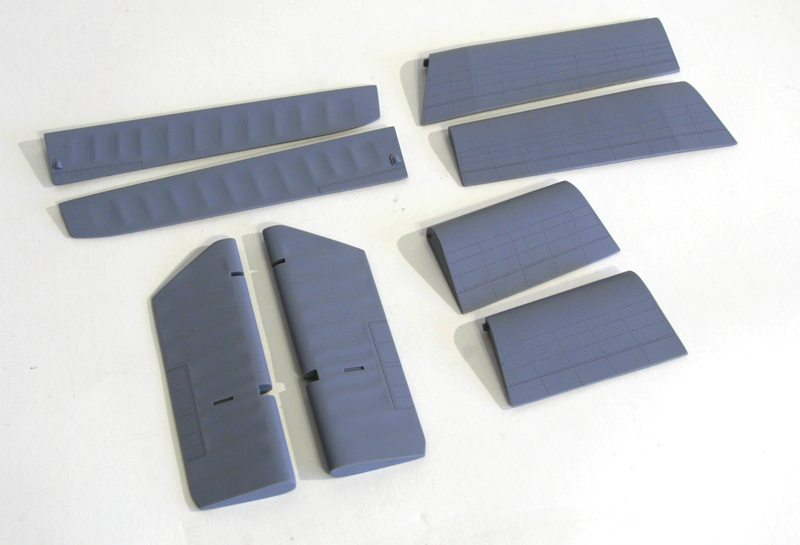

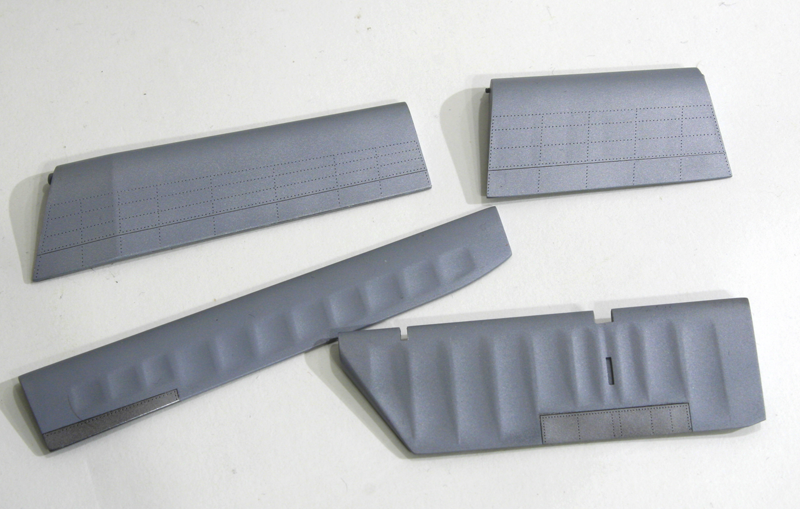

To illustrate the fabric on the movable controls I tried dull aluminum's which gives a very good difference from the metal of the airframe and painted the trim tabs in aluminum's to make them stand out the dull fabric colour.

The good thing about these non bright colours from alclad is that I can spray them over a coat of Mr Surfacer which for me is way easier than a gloss black should I have chosen aluminum's or airframe aluminum's.

Here are the test parts primed with Mr Surfacer:

and painted in the alclad colours referenced above:

Once they are all assembled on the tail unit, the nuances stand out pretty well:

The dark picture don't do them justice - It's hard to get good lights in this time of the year

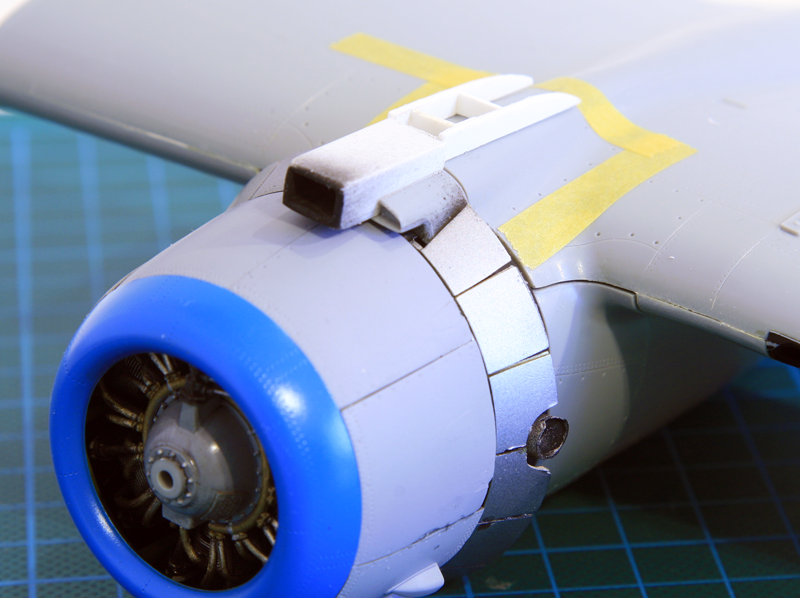

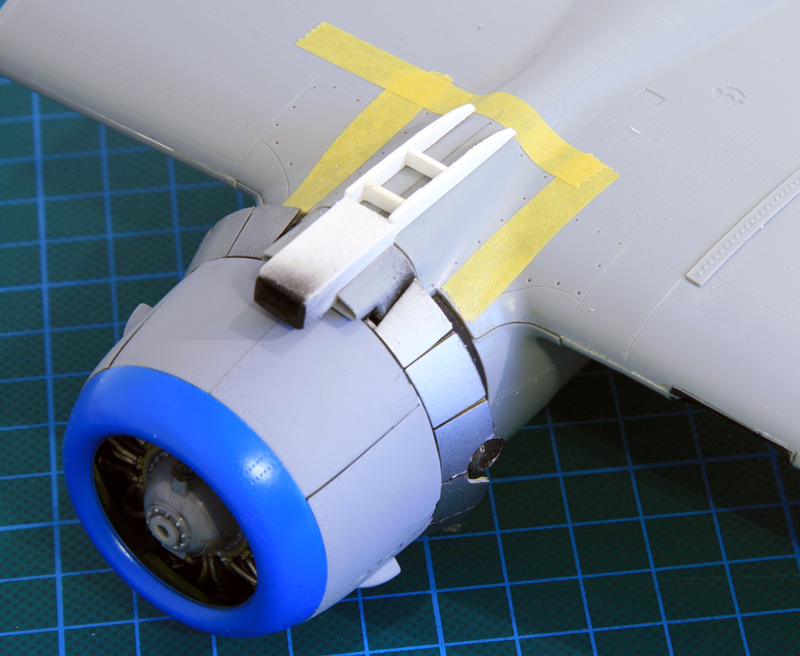

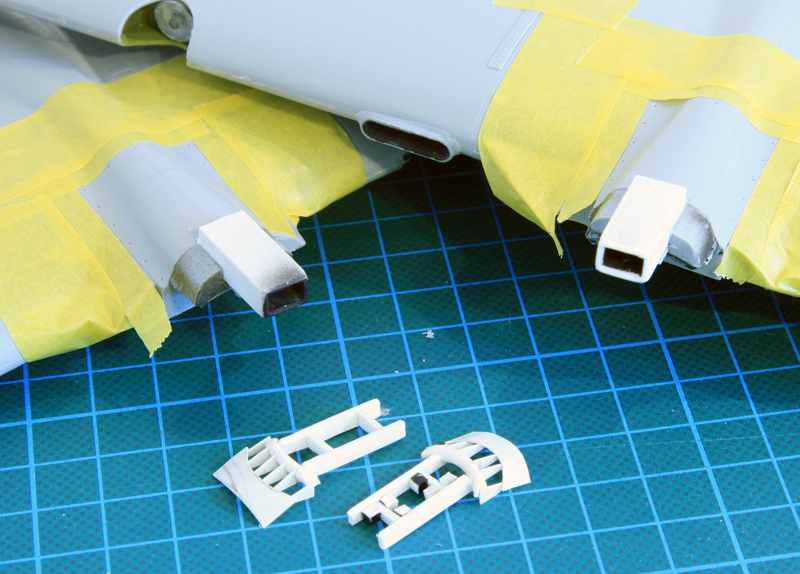

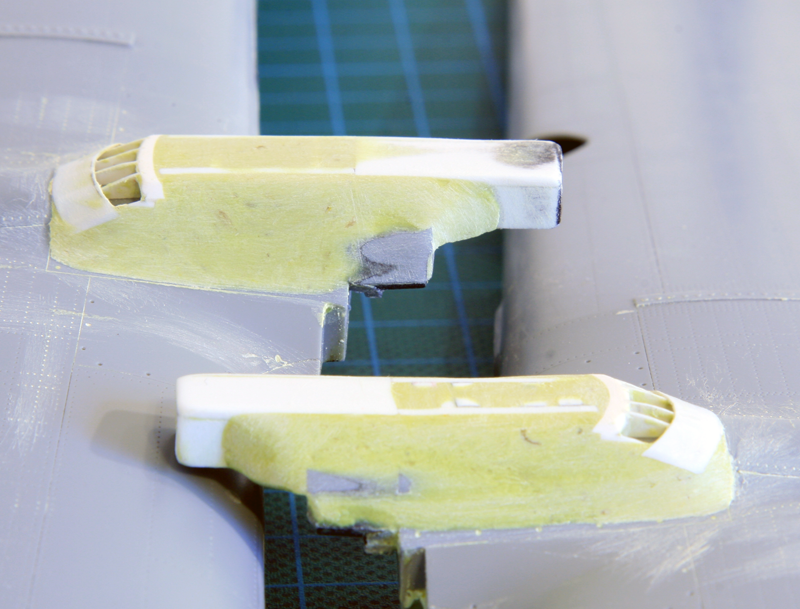

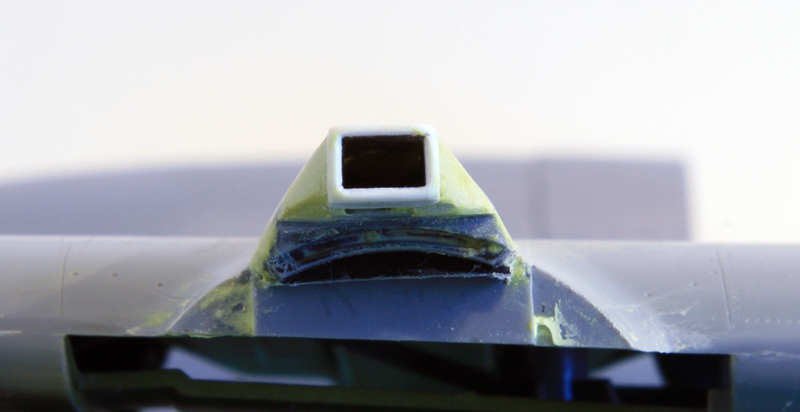

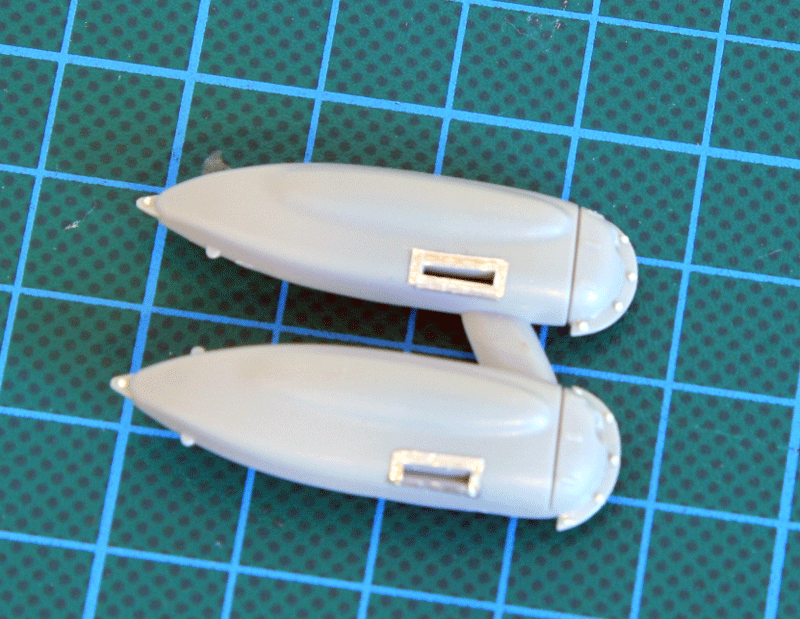

The carb intake challenge:

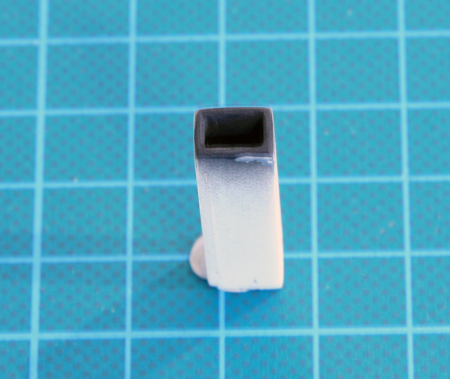

I knew right from the start that converting the engines exhausts and carburetor intake was going to be a huge challenge. After studying a lot of pictures adapted to scale, I calculated the front intake to be 8x5mm

I used a perfectly aligned picture of a B-25 engine and scaled it to the kit's parts. printed it and put the kit's parts on top of it. Then simply measured the rectangular shape:

For the side of the intake, I tried to find again a perfectly aligned picture of the side view, scaled it to the kit's part and print.

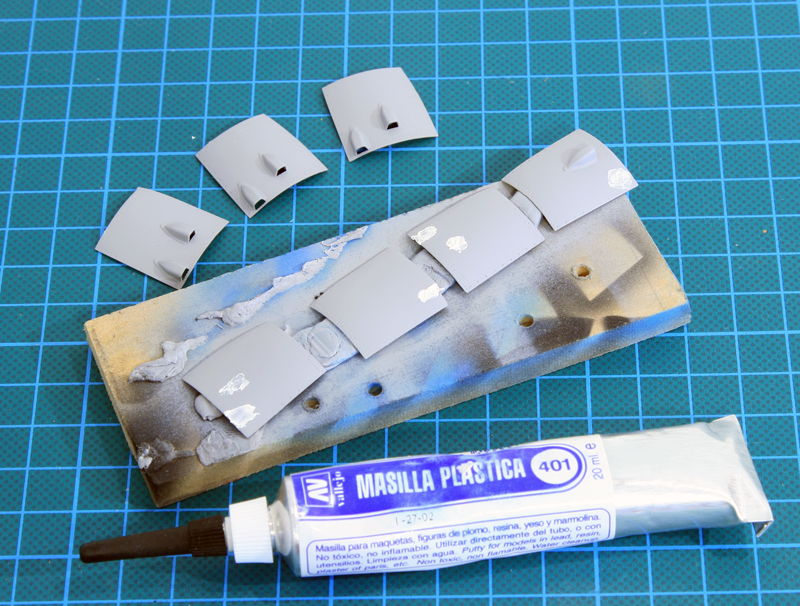

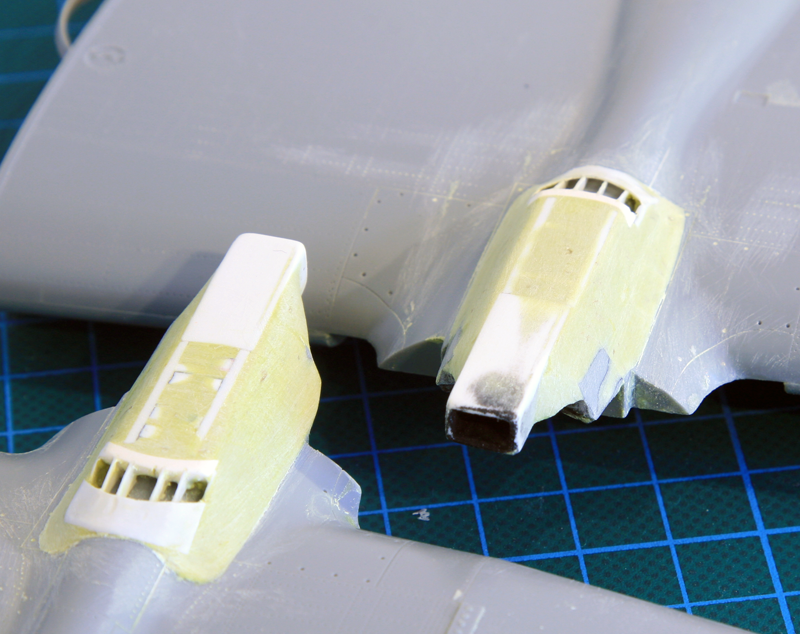

The engine pods are undergoing surgical modifications:

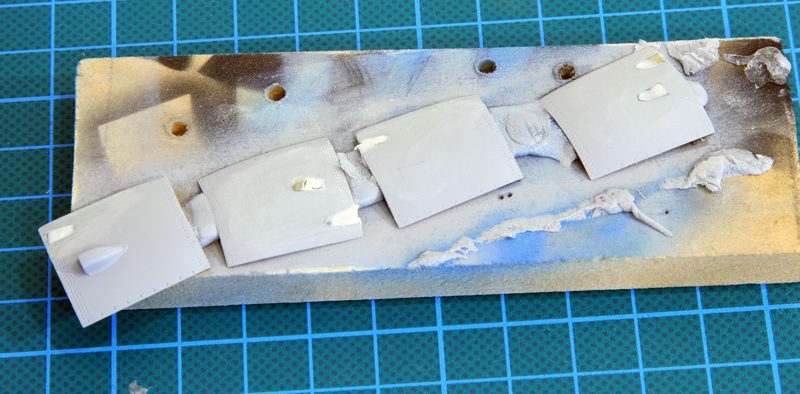

First the Clayton exhausts were removed accordingly from the engine panels. The plastic was simply cut away from the parts. A plastic sheet was glued on the internal wall of the panel and the hole was then filled with Tamiya light curing putty. Once dry and sanded flat, I added Vallejo white putty and sanded again. Checked my work with a coat of Mr Surfacer and applied super glue on the holes remaining. Sanded flat again before the glue was completely cured.

One of the two hole is very close to the panel edge so it is very fragile. I broke two out of four panels at that tiny junction point. It's almost impossible to repair on the panel, but it will be very easily repaired once the panels are on the engine cowls, so I left that for later.

Parts 3, 5 and 7 were left untouched. One Clayton exhaust from part 4 was removed (the upper one) and both Clayton exhaust were removed from part 1, 2 and 6.

Accordingly, only the relevant internal exhaust ducts were glued to the cylinders (15, 22,16,10, 17 and 11)

The new exhaust collector that goes outboard the engine has been shaped by lightly heating a transparent plastic rod to about an angle of 80° then cut to shape. The outer wall thinned with the dremel.

To place it at the relevant spot a bit of angled sanding is required on the cowl flaps support plate and the exhaust is maintained in place with an extra angled support on the engine rear face.

Obviously two cowl flaps have been cut to let the exhaust pass through.

the exhaust will be weathered later on as the whole assembly still need to be primed and painted

The new carburetor intake has been built with 1mm plasticard to create a 8x5mm rectangle.

The intake lip has been sanded round.

The original intake has been cut to place the new one just for positioning purposes. Once happy with the result, I will further cut the old intake remaining sides and shape the new intake with milliput.

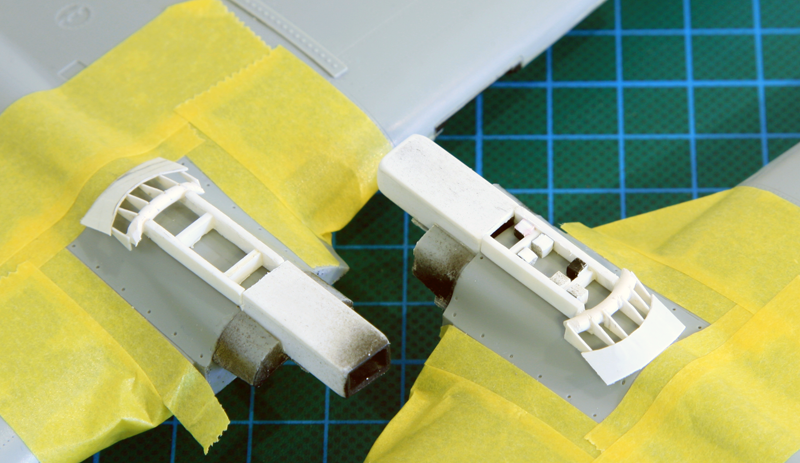

The biggest challenge is the rear openings. I wanted to milliput the whole part but if I do that I will have lots of trouble making that part, so I decided to make a structure in plasticard first and milliput around the structure.

Here are the attempts at the rear structure of the carburetor intake:

I'll now try to shape that specific part:

I first made the shape of the rear vents (?) with bits of plastics

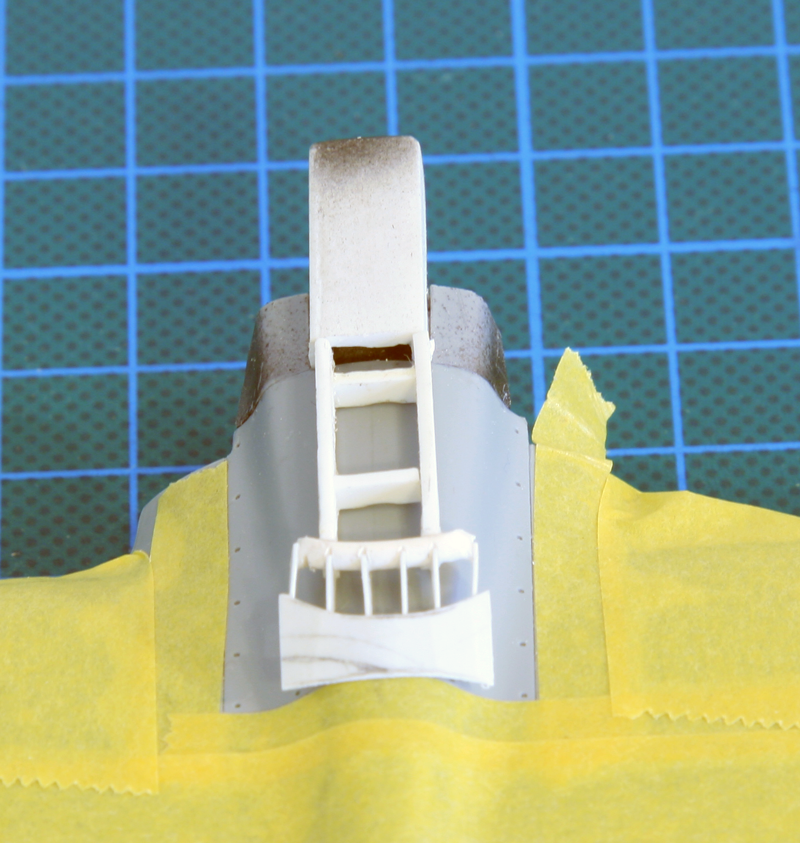

To avoid having to build to whole engine nacelles before shaping the new carburetor intake I cut the top of the engine rear face supporting the cowl flaps so I could glue that bit on the top of the wing.

That way I can build the nacelle, engine and gear later on and probably avoid breaking the whole assembly as I shape and sand the carburetor parts.

I protected the wing with masking tape as my milliput work is usually messy :)

Once happy with the positioning I glued all scratched part to the top wings and started milliputting the new shape around the plasticard structure.

The milliput was smoothed with water to be as shaped and as smooth as possible

And then coarse sanded before removing the mask. Next step is to sand with finer grit and get it smooth.

I know it's far from the perfect shape. I took some shortcuts to make my life easier like having the rear part horizontal up to the vents where normally they should be angled down already. But I couldn't find an easy way to make that down slope.

The front face looks good though. The rest is far from perfect but this is an area where I am really not comfortable and I'm happy with the result I could get.

I will now finish it smooth and soften the rear edges a bit more before a first layer of Mr Surfacer

The next challenge after modifying to carb intake was to close the fuselage halves.

With all the stuff I added inside, and especially the wires and the PCB and the added rear compartment floor which is missing from the kit, I needed to ensure that all was working and fitting fine before closing the fuselage.

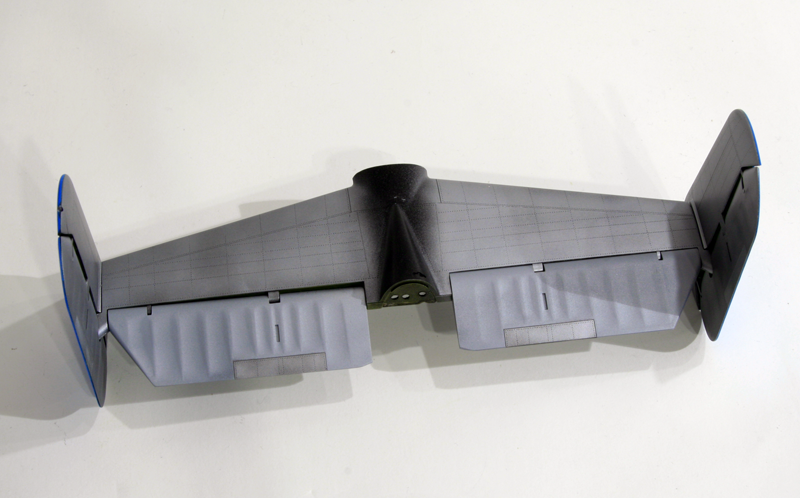

Anyway, before taking on that challenge, I wanted to do some real modelism and worked on assembling and painting the wings and the engine pods.

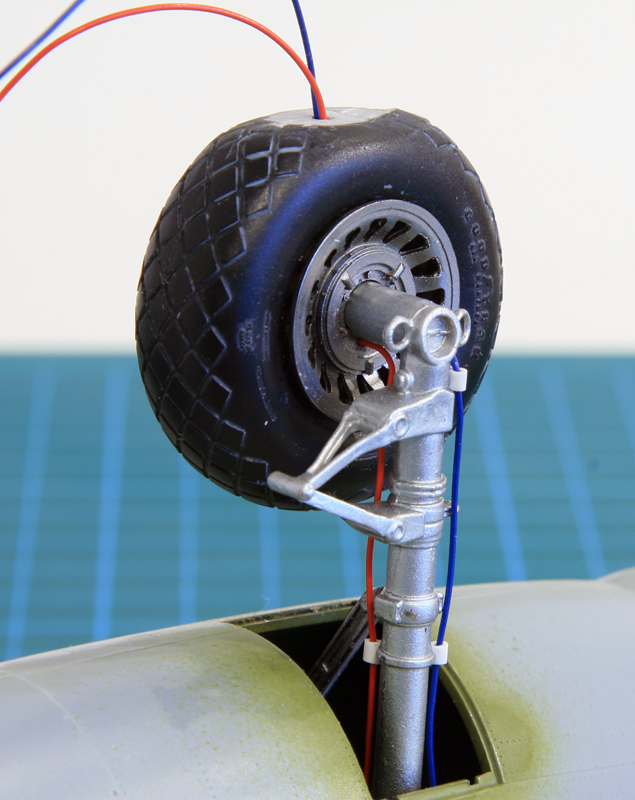

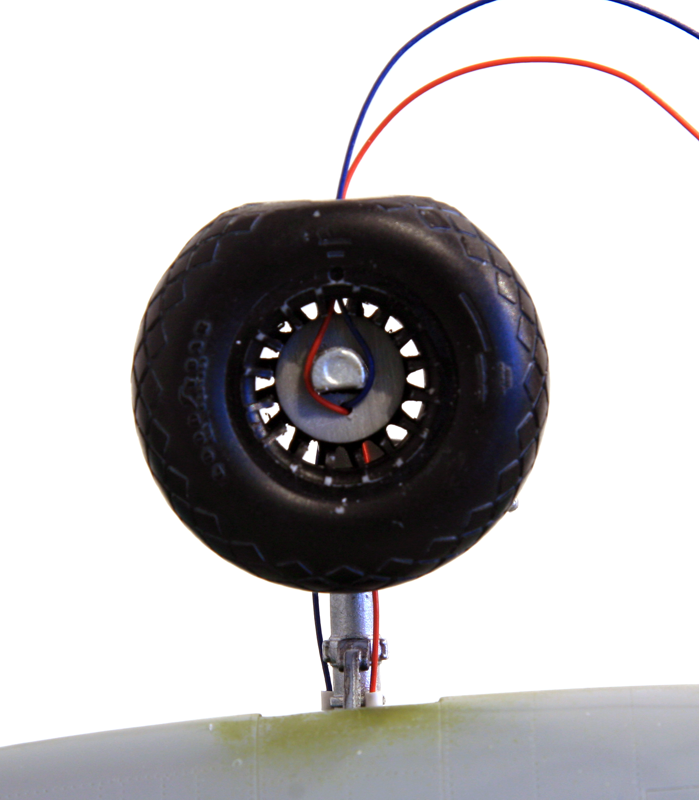

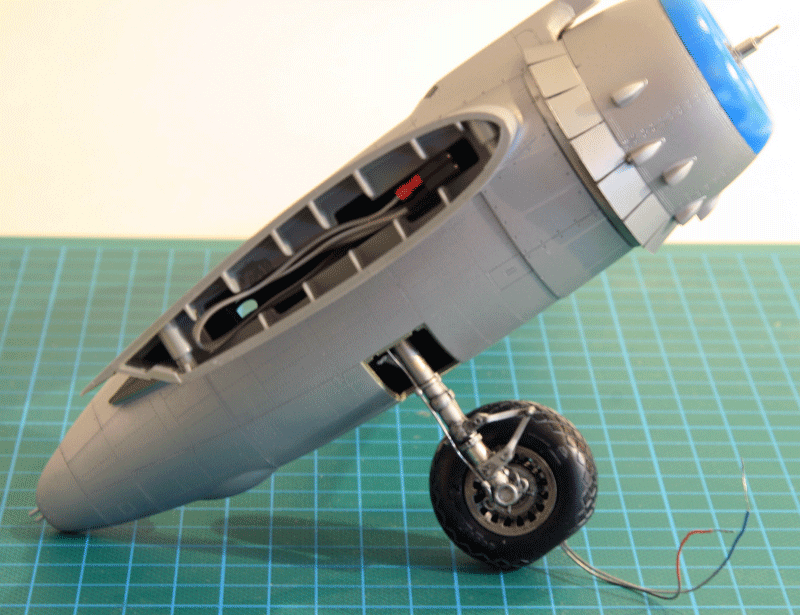

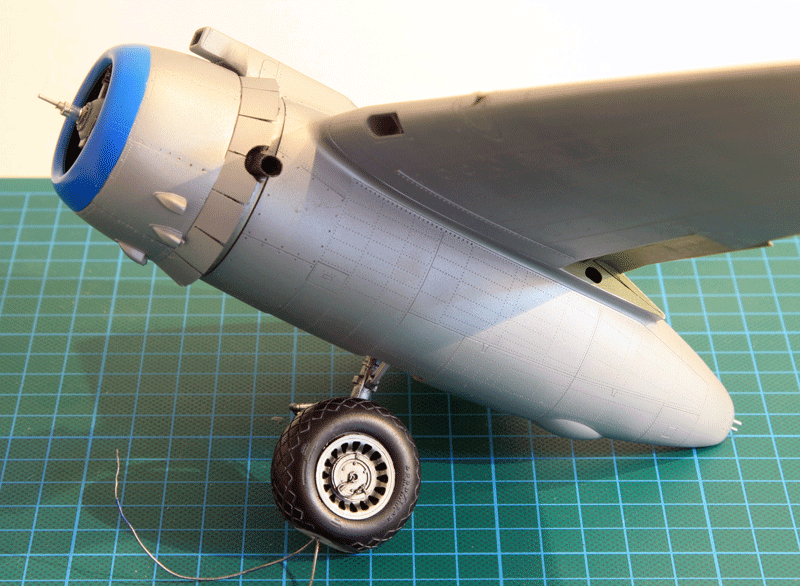

The trick was to decide where to go with the prop motor wires. I could go through the wings to the fuselage internal or go through the main gear legs.

I decided to externalize the engine controls into the base of the model. So each wires from the engine are going to go through the main gear leg and tire into the base.

The wires replace kit parts J21/22 & J17/18. They enter the wheel, go around the axis and descent through the Tyre into the ground where they will go through the base of the model.

The pods fit fine on the wing and no putty was really necessary. Just a bit of sanding at the rear of the pod where it meets the top of the wing. the cowls were a bit more delicate to assemble, but that's mostly due to the motors fitting in there.

Inside the wings I wired the landing light and the position light (using scratch build fiber optics). These wires will go through the fuselage to the PCB placed behind the bomb bay.

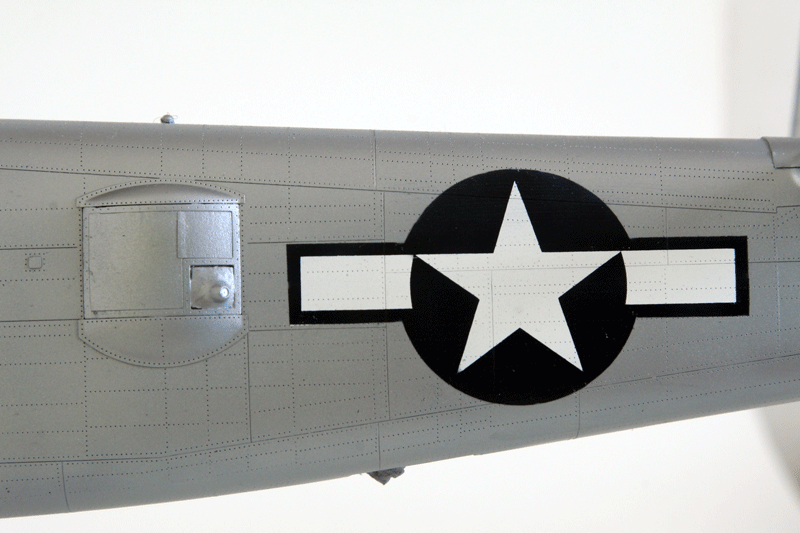

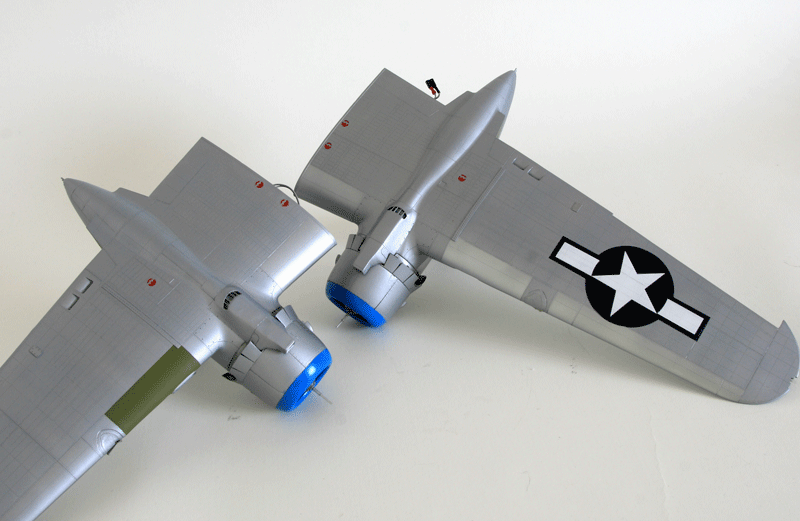

The wings were primed with Mr Surfacer 1000 and then sprayed straight with ALCLAD semi-Matt aluminum's. Maid in the shade aluminum's doesn't really shine. The alclad reacted fine on Mr Surfacer.

The US national insignia were painted with the Maketar masks which I used for the first time. I used the Kabuki version and they gave me plenty of satisfaction. It took a lot of time but enjoyable time doing paintwork which is by far more enjoyable than soldering wires for the led :)

No issue at all with kabuki on the alclad. Semi-Matt aluminum's is pretty solid.

I initially planned to place the printed Circuit Board (PCB) on top of the bomb bay but unfortunately the ceiling clearance is just too short.

I had to trick the rear of the bomb bay with a false compartment and slide the PCB in there.

Checking the lights before closing the fuselage.

Two wires go out of the fuselage to the wings. To ensure the clearance for these wires I dug into the fuselage and bomb bay walls. The wires will go through the sliding mechanism of the wings. That will let me disconnect the wires should I need to disassemble the wings from the fuselage

The tail connects as well for the left top tail light.

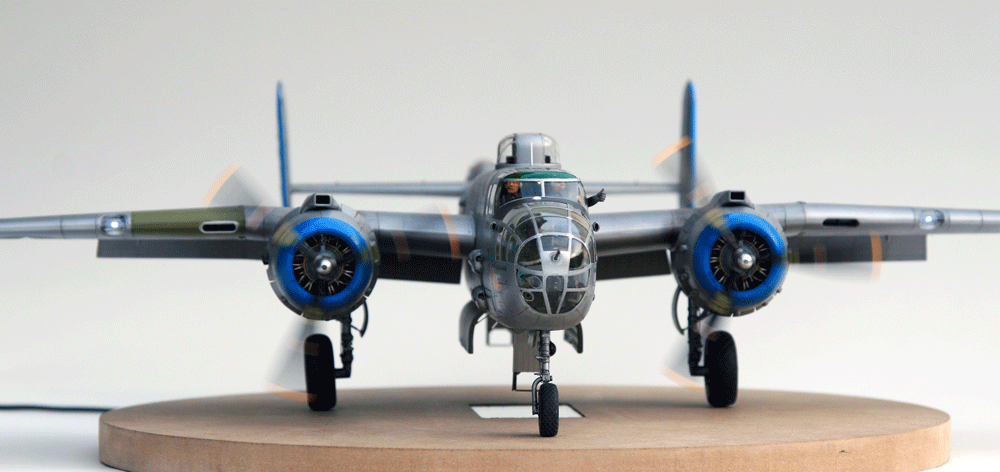

Both Anti collision red lights flash in opposition, the rest of the flights are flood lights and remain steady. There are two in the rear compartment, one in the bomb bay, one in the front compartment and provisions for one in the nose compartment.

The wire providing power to the PCB are routed to the nose gear bay and will go down along the nose gear leg and into the Wheel into the base of the model.

Seats were added into the rear compartment of Maid in the Shade. The cabin has been modified to transport passengers during airshow rides. I took a bit of artistic licence in the rear compartment seat positioning as the cabin will not be highly visible anyway.

The .50 mechanism was quickly detailed nevertheless

Front compartment was also detailed. the top turret support will not be installed and instead two passengers seats were added on the rear bulkhead.

Seats are scratch built and I used the Eduard coloured seat belts kits.

They are far from easy to work with. They feel very unnatural because you can't really bend them naturally. If you do, the paint layer might actually pop from the PE.

In some cases, if you follow instructions you must bend a part at 180° to insert a buckle and doing so you will inevitably destroy the coloured layer.

Probably the last time I use these, they were included in the Big ed set but honestly, they are not worth using.

A simple painted lead sheet and cut to size with PE buckles give much better resin than full PE coloured seat belts.

I heard a lot of good about the HGW fabric seat belts but I never had an opportunity to test them yet.

The scratched floor in the rear compartment might create fitting issues when closing the fuselage so I added some guides to ensure it was moving above the internal support. In dry fit attempts, the floor got stuck under the support creating a gap at the fuselage joint.

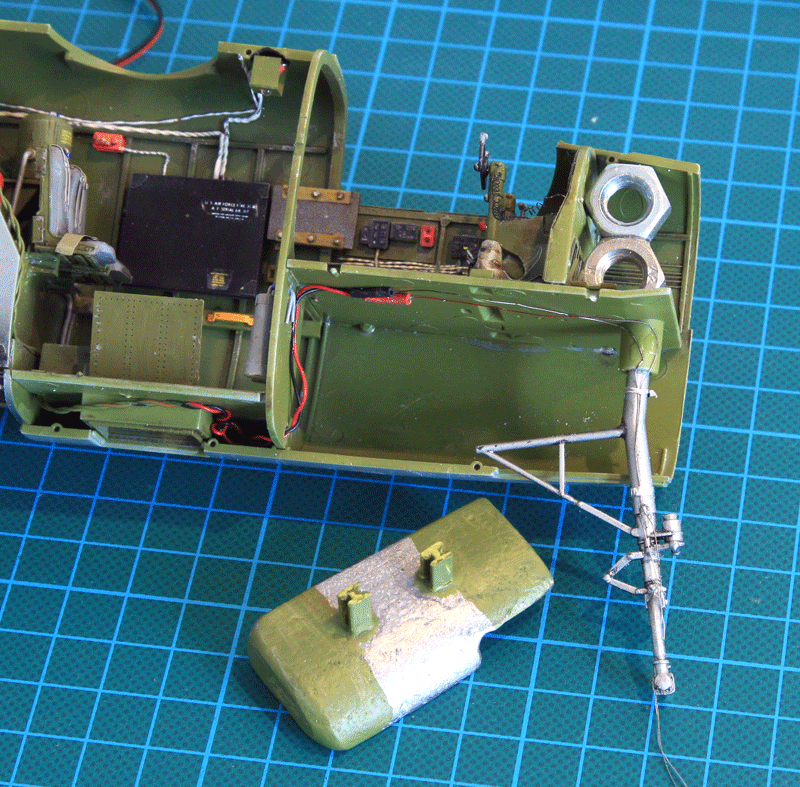

I had a bit of trouble with the Terry Dean nose weights. The longer weight naturally goes on the side opposite the passage to the nose. As the cockpit floor was glued on the other side, care was taken to ensure the weight didn't conflict with it.

So I had to angle it a bit to ensure I didn't create fitting issues.

I couldn't really sort the shorter weight position. the cut and the curves didn't get me a natural position so I ended up improvising. I put some spacers from the left wall so the nose weight wasn't too visible from the nose. As I didn't build the passageway, I didn't want the nose weight to be fully aligned with the large hole visible from the nose.

I don't want these weight to move so I glued them firmly in place, and made sure the glue was well dried before closing the fuselage to ensure liquid glue wouldn't soften the plastic.

I ended up with a bit of an awkward position with the nose weights, but who cares, nobody will know :)

Don't mind the tail;, a wire makes it unbalanced.

It's a milestone in this build. With the fuselage finally closed, the model finally could be assembled. That's were you realize how huge this beast is!!

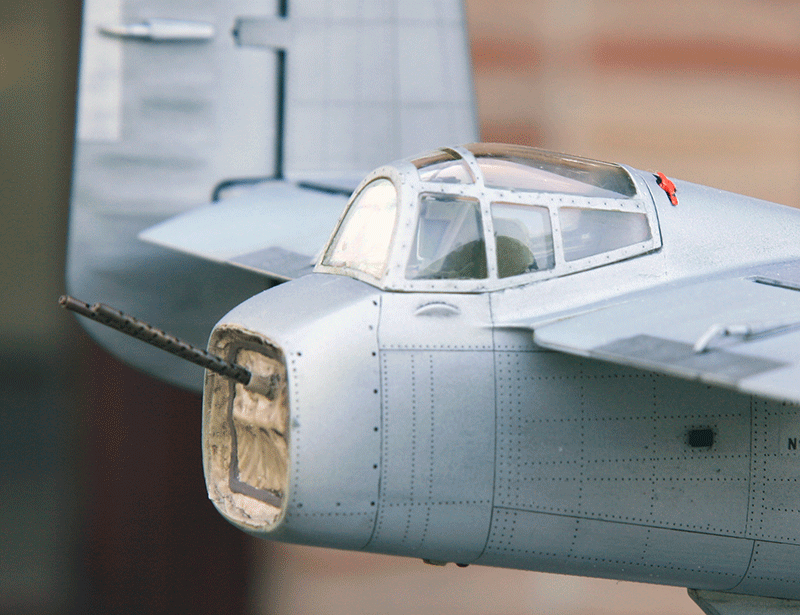

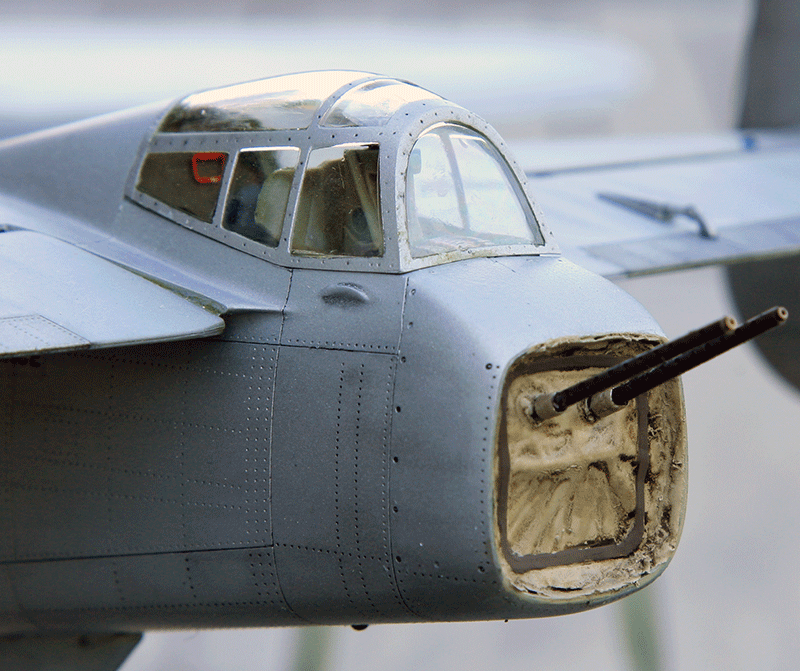

some minor detailing of the gun pods:

The fuselage is ready for priming, ailerons and rudder flight are already painted with dull aluminum's for fabric covered surfaces, the tabs are aluminum's and contrast heavily with the flat parts.

The parts inside the wings when the aircraft is clean are painted dark grey

The flaps which are metal are painted semi Matt aluminum's, like the rest of the Aircraft

The US National insignias on the fuselage were painted with the opposite masks method.

This allowed me to tests both method of mask painting. Have a look at the specific articles about using masks if you're interested to know more.

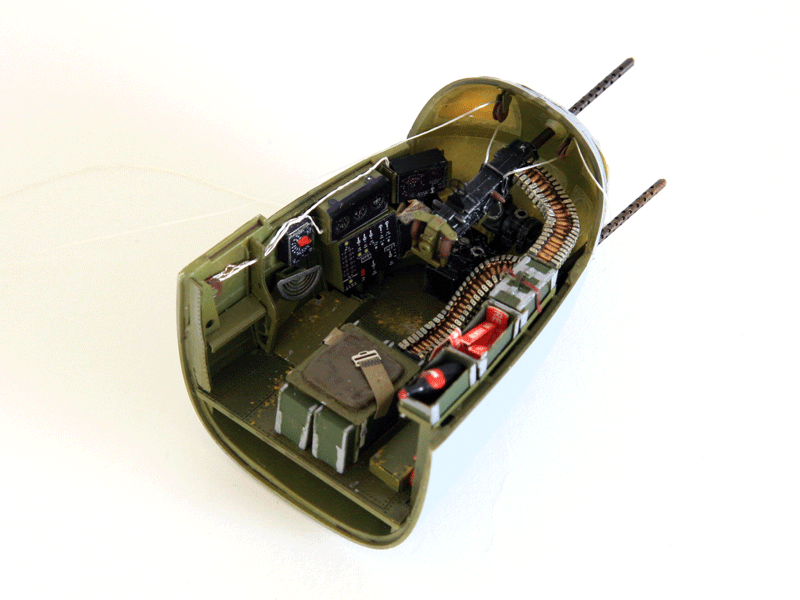

Lets work on the nose section which is a small model by itself within the model:

The Eduard ammo boxes were cut shorter - it's actually very easy to make them lower as the usual ammo boxes by simply snapping both top side off.

Two of them were left opened with Remove before flight tags and an unsecured bottle (not a good idea I'd guess)

And some details:

Decals

As i pointed out earlier, this project will require homemade decals.

I usually printed my decals at work on a laser printer. Unfortunately that old laser printer has been retired from service.

I thus turned to ink jet printing on the home printer. I was a little bit concerned about ink jet being as good in quality as laser, but I'd give it a try anyway.

First step was to source a few sheets of ink jet decal paper from expert choice decals.

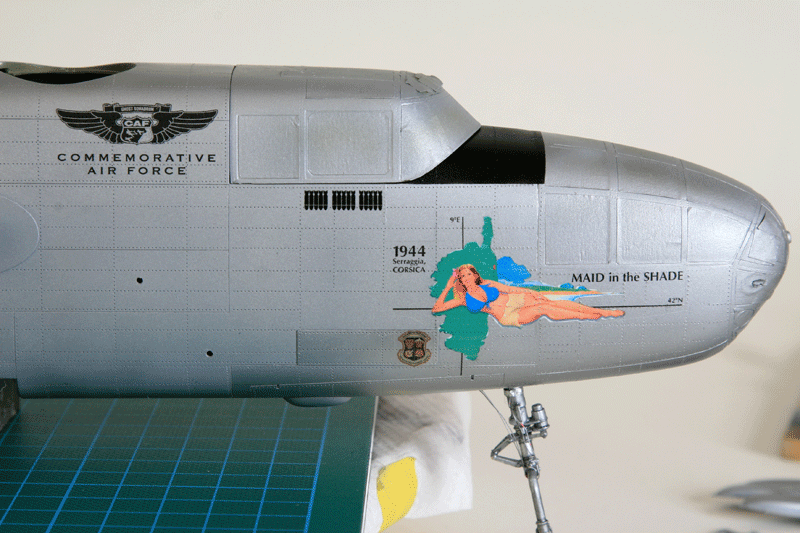

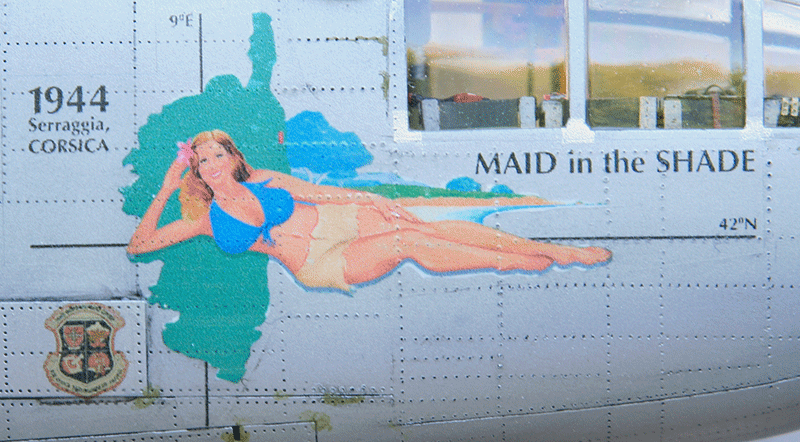

The artwork were redone as well. Maid in the Shade recently had the pinups repainted. My original artwork used the old pinup design. Since I'll do the 2016 version of Maid in the Shade I needed to change a few things.

The first step after completion of the artwork design is to print the decals on plain white paper and check dimension and fitting on the model:

Once satisfied with the dimensions, I then taped a piece of transparent ink jet decal on a paper sheet and printed the decals

I'm pretty glad with how this turned out. The ink jet result is pretty good and much more vivid than on the white paper.

Matter of fact, this may be much better than the results I had before on the laser printer.

The problem with homemade decals is that some light colours might not be opaque enough to cover the sometime dark paint on the model. In this case, the aluminum's is light but I'm a bit concerned about having a dull pinup color if I simply put the decal on the model.

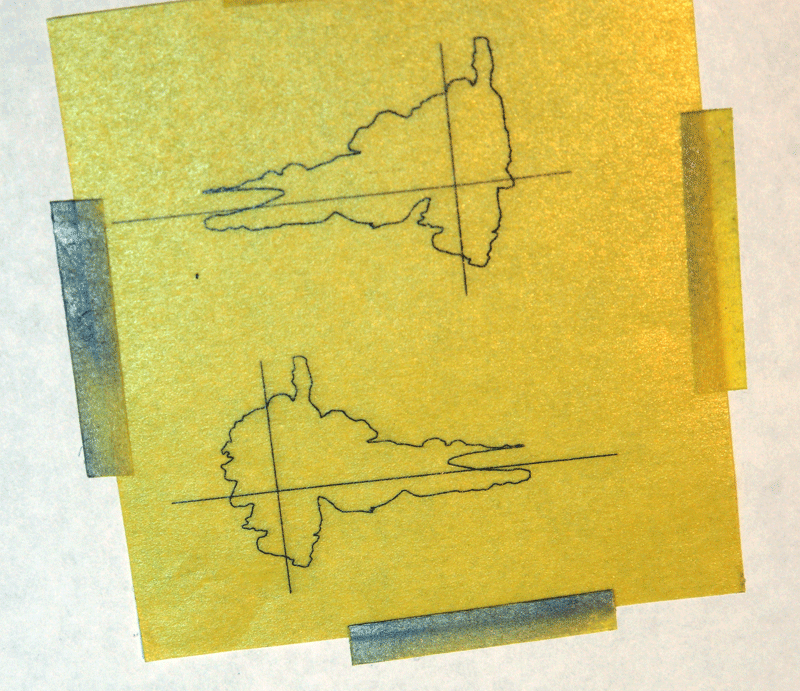

To give the decals more brightness I decided to create a mask so I could paint the background of the artwork on the fuselage in white before applying the decal:

I created a contour mask and printed on a blank sheet of kabuki paper.

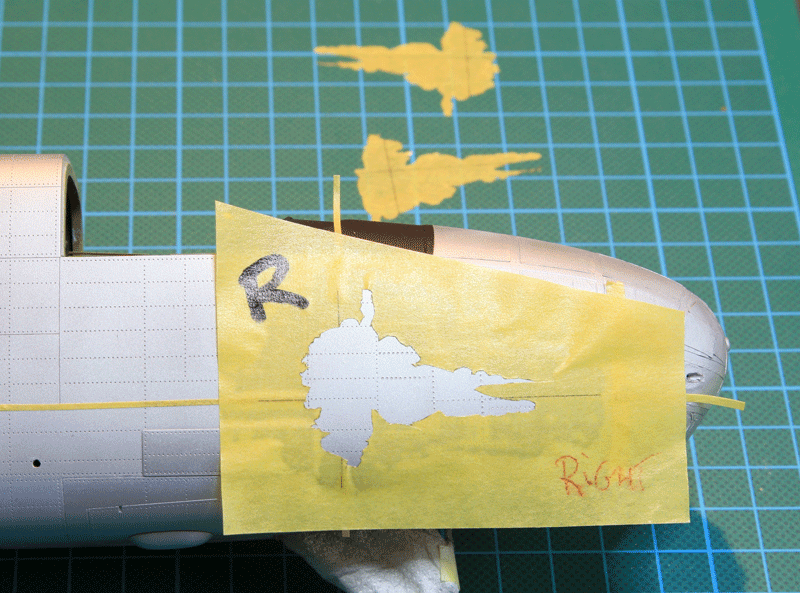

I'll just need to cut the mask and use the black vertical and horizontal lines to align the mask on the model, and paint a thin white layer as background:

As you see, I had to cheat a bit by rounding the contour of Corsica to make the cutting a bit easier :)

First step was to carefully cut and align the nose art mask on the nose:

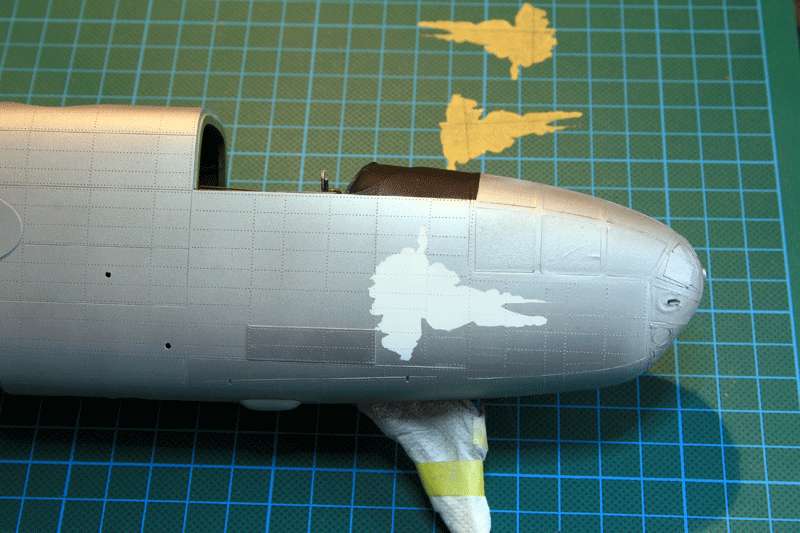

then paint white:

And apply the decals.

The large nose art decals are very thin (on purpose) and very fragile. So I didn't have the luxury to move them a lot. They were also very sticky and I was very concerned I might tear them while moving. So I decided to live with the small bits of white outline I have left.

I will correct that later one with a bit of paint touch ups.

There is no doubt that the white background mask was critical. The decals were indeed very transparent and wouldn't have stand so good on the semi Matt aluminum's without the white background.

To some extend you can see what would have happened with the small brown patch. The decals are dark colours but still don't stand enough of the airframe colour. The nose art being light colours would have been much worse

The tail decals were much easier to place:

Testing some variation of metal colour on the wings. Alclad aluminum's for the leading edge (except the leading edge in primer which seems to be a 2016 feature of Maid in the shade (that's probably going to be repainted soon on the real one but I love the spot of color it gives the aircraft :)

I also made some tests about which varnish to use before the decals. I never tried the Gloss cote from alclad and I wanted to but was concerned a bit with the subtle oil wash I'd give after decals.

Usually I always ensure that the gloss coat is opposite to the wash (if wash is oil, gloss is water based)

So I tested on the inner flaps and when I apply wash (tamiya panel line accent) over the alclad gloss coat, you can clearly see that the wash diluted the varnish and a gloss/flat difference clearly appears.

I think I'll revert to the old safe value acrylic X22 for basic pre decal gloss coat.

Flight crew

As the model might have lights on and engine running, i needed a flight crew. So let me introduce you Billy and Mike

Billy has just finished starting the N° 2 engine and after a quick check of the gages is telling Jamie who's on the ground manning the fire extinguisher that the engines gages are OK. :)

Both figures were assembled from the scrap box. The arm were adapted to fit the B-25 cockpit. Mike is holding the yoke while Billy gives a thumb up through the opened cockpit window. He also has checklists on his right hand.

Initial assembly

Dry fit in the cockpit.

The main concern was to ensure that the pilots wouldn't interfere with the transparent canopy part when placed on the fuselage. To make sure it fitted I had to lower the seats a bit. I also cheated a bit with the yoke to ensure that Mike had it firmly in his hands.

The seat belts which are not weathered yet are made with the Eduard PE buckles. I discarded the Eduard PE belts as it's way to o hard to bend them around the clothes curves. I replaced them with lead foil.

The David Clark headsets were scratched.

Not many civilians pilot are available so I did my best with my limited experience on figure painting and the limited parts I had at my disposal.

Once the canopy will be closed I'm pretty sure it's going to be enough

Not much of the pit will be visible once everything is closed down. I nevertheless tried to make a compass on the main glare shield which should be well visible

The rear gun cover was made from aluminum's foil. Earlier in the build I considered the Grey Matter Figure part which is a much better than the kit's part which is really bad IMHO.

But Maid in the Shade has a real flat canvas so even the GMF part wouldn't cut it.

Making the part was very simple, just cut aluminum's foil, paint in tan and done. The extra zipper was also made with aluminum's foil. It's a bit too wide, but that will do.

The guns are brass guns from Master. They are actually coming from the B-17 set. I will never use anything else than these brass gun. They are way better than the plastics ones and much easier to use than the photo etch gun you have to roll closed.

These are not painted, simply burnished with the AK metal burnishing fluid.

Maid in the Shade features modern radio and navigation systems and the antennas are different from the WWII models, they needed to be scratched.

Quick and dirty work on the top fuselage in front of the (modern as well) anti collision light:

The horizontal stabilizers have 4 small blister blue lights. These were made with the templates Eduard PE fret provided. There are a lot of them on the Eduard PE and I always keep these.

Just heat a bit of transparent sprue Under a candle and press it in the template while hot to get a nice nav light.

There are actually 2 more on the vertical tail, but they are left transparent.

Note also the added red handle to release the tail gunner canopy and I'm pretty happy with the tonal differences between the fabric covered controls and the metal parts of the tail and trim tabs

The main wheels got some detail painting. Can you guess that there are actually 2 wires descending from the wing to the base for the engine power in there?

Custom nose art decals printed on regular ink jet decal paper with a white mask applied before decal. It's the worst of the two, the other side actually came out much better:

The led in the top turret compartment illuminates the cockpit as well:

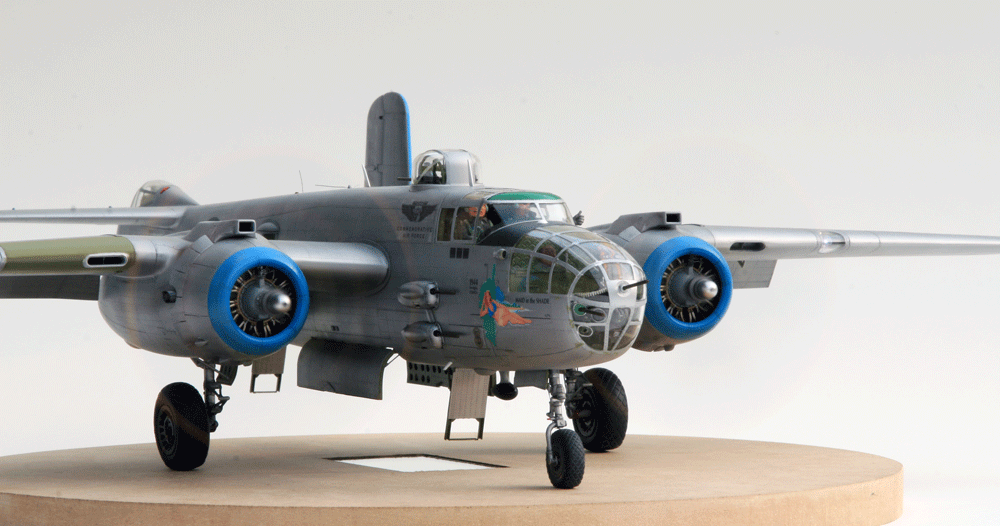

The converted carburetor intake:

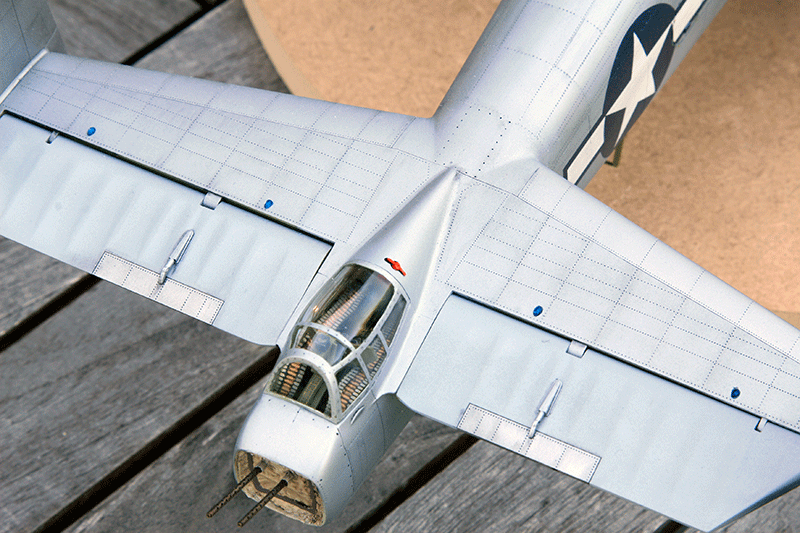

Top view of the cockpit and bomber compartment

The modified exhaust on the outboard of the engines

AMS propeller

The light Inside the waist compartment saves a bit the invisible details Inside the fuselage

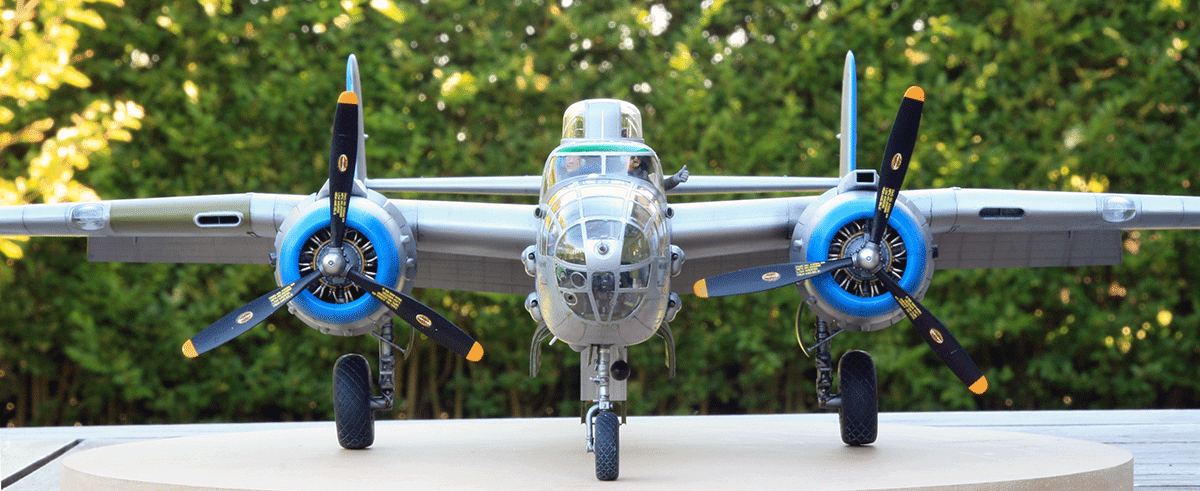

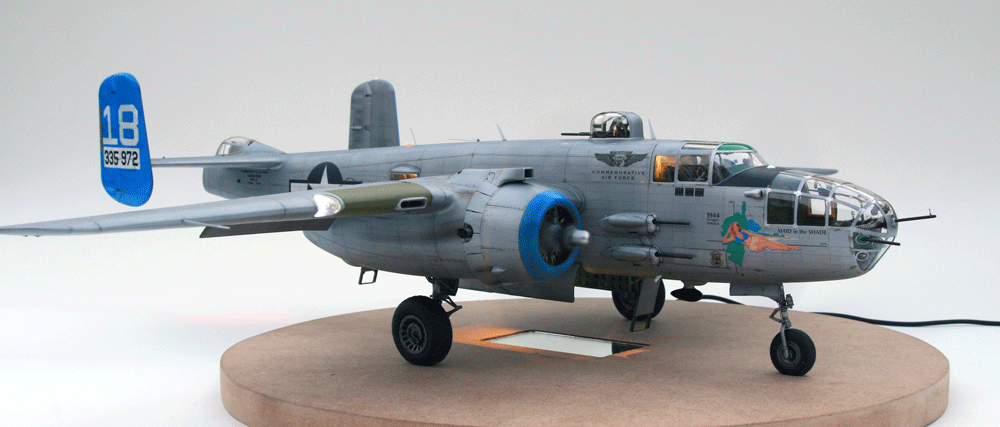

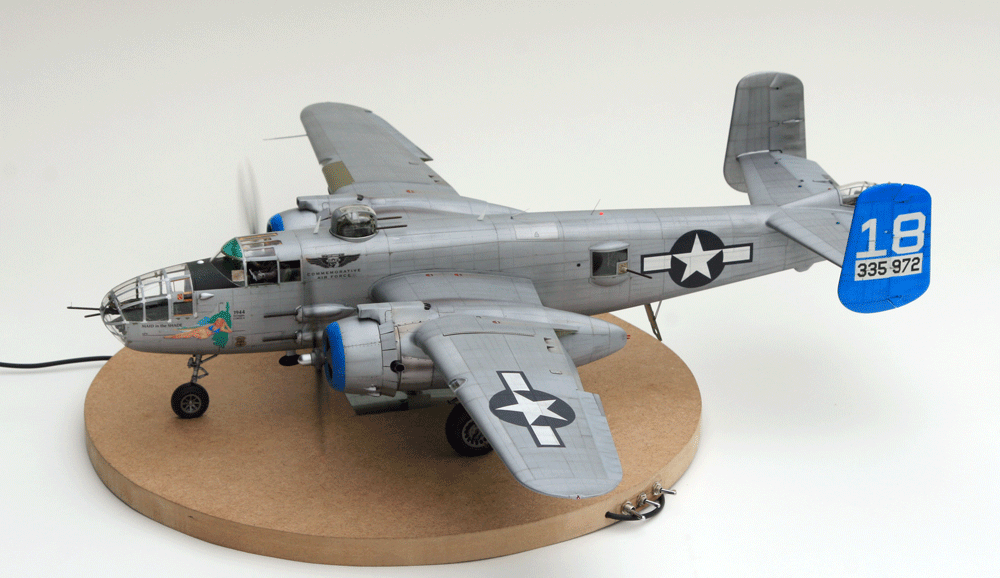

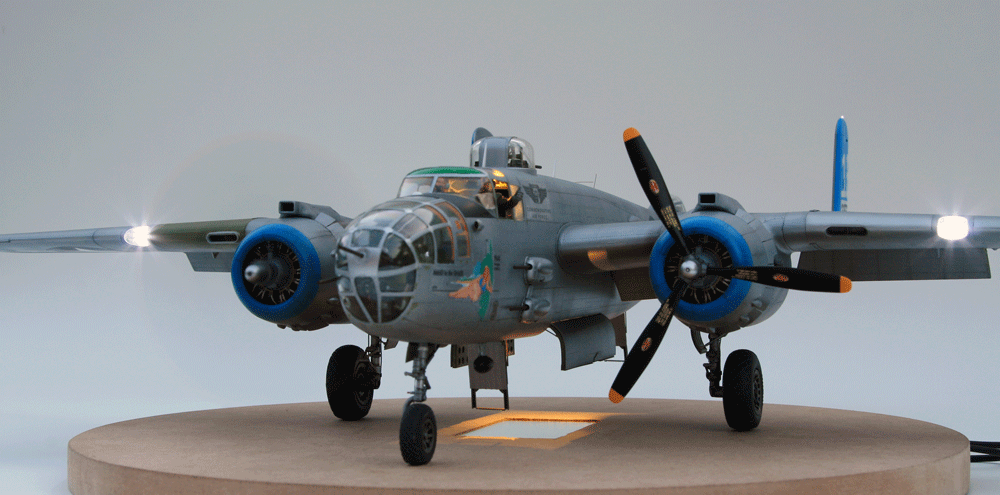

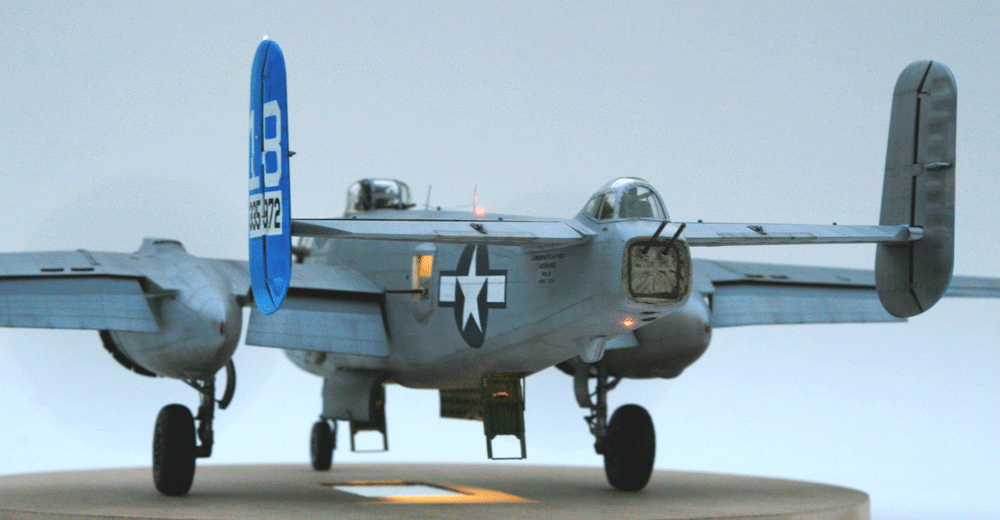

Pictures of the finished model:

Engines OFF

The base has three switches. One for the left engine, one for the right engine and one for all the lights.

The finished model featured in a short video where engines and flashing lights are better seen:

hi, where did you get the circuit board for your light set up? Please reply to me through busntruck at yahoo dot ca

ReplyDelete